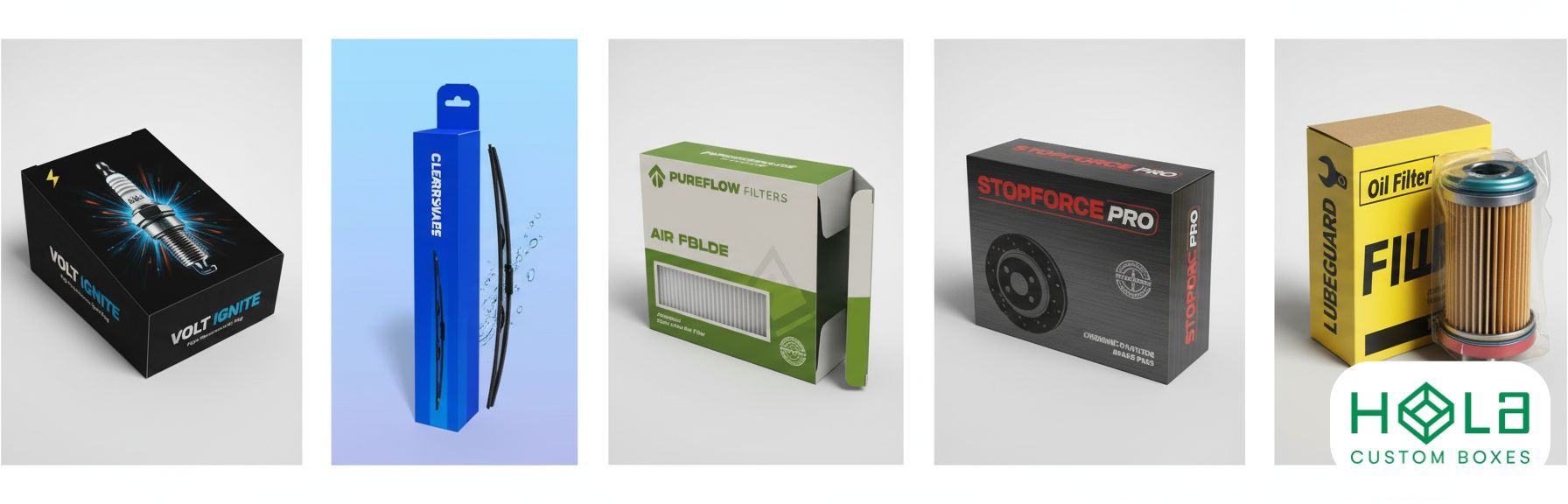

Custom Automotive Packaging for Auto Parts Boxes Wholesale

In the dynamic automotive industry, where precision and protection are paramount, custom automotive packaging plays a pivotal role in ensuring that auto parts reach their destination in optimal condition. From delicate sensors to robust engine components, the right packaging solution, including automotive product packaging boxes, safeguards against damage during transit, reflects brand value, and streamlines the supply chain. This article delves into the intricacies of custom automotive product packaging, exploring its significance, key components, and the benefits of choosing custom options for auto parts boxes wholesale.

Understanding Automotive Packaging

What is Automotive Packaging?

Automotive packaging encompasses the design and production of packaging solutions specifically tailored for auto parts. This specialized field of product packaging addresses the unique challenges of protecting automotive products, which range from small, fragile electronic components to large, heavy mechanical parts. The primary goal of automotive packaging is to ensure that vehicle parts arrive at their destination undamaged, maintaining their quality and functionality within their auto boxes. Effective auto parts packaging, including auto accessories packaging, considers factors such as cushioning, immobilization, and resistance to environmental elements.

Importance of Packaging in the Automotive Industry

In the automotive industry, the importance of robust and reliable packaging cannot be overstated. Auto parts, including car parts, often endure long and complex supply chains, making them susceptible to damage from handling, vibration, and environmental factors. High-quality automotive packaging is essential for protecting these parts, ensuring they arrive at assembly plants or repair shops in perfect condition. Moreover, effective product packaging reflects the quality of the automotive products and reinforces brand reputation, while optimized auto parts packaging solutions can reduce shipping costs and minimize waste, contributing to a more sustainable and efficient operation.

Key Components of Auto Parts Packaging

Effective auto parts packaging typically involves a combination of packaging materials and box design elements tailored to the specific requirements of the automotive parts being shipped. There are a few key considerations in creating effective packaging:

- The choice of material is crucial for providing the necessary durability and protection.

- Inserts may be used to immobilize parts within the auto parts box, preventing movement and potential damage.

Box style, custom size, and printing method for automotive product packaging further enhance the packaging's functionality and visual appeal. Custom packaging solutions provide an added layer of protection and brand recognition.

Types of Auto Parts Boxes

Common Box Styles for Automotive Products

The automotive industry utilizes a variety of packaging boxes to cater to the diverse sizes and shapes of auto parts. Common box styles include regular slotted containers (RSCs), which are cost-effective and versatile for general packaging needs. Die-cut boxes offer customized shapes and sizes, ideal for uniquely shaped automotive parts requiring a snug fit. Corrugated box options are popular for their strength and durability, providing excellent protection during transit. Specialized parts box packaging styles, such as those with built-in inserts or dividers, are designed to immobilize and protect fragile auto parts. The selection of the appropriate box style, such as a cardboard box, is crucial for ensuring the safe and efficient transport of automotive products.

Benefits of Custom Auto Parts Boxes

Custom automotive boxes offer numerous advantages over standard packaging solutions. In particular, custom solutions offer benefits such as:

- Tailoring the box design to minimize wasted space, which reduces shipping costs and promotes sustainability.

- Enhancing brand visibility through custom printing on the boxes.

Customized packaging can also incorporate specialized inserts to provide superior protection against shocks and vibrations. Custom packaging solutions, including automotive product packaging, also allow for the inclusion of specific handling instructions or branding elements, improving the overall customer experience. Investing in custom auto parts packaging demonstrates a commitment to quality and attention to detail.

Durability and Material Options for Automotive Boxes

Durability is paramount when selecting packaging materials for automotive boxes. Corrugate is a popular choice due to its strength. The thickness and construction of the corrugated box can be customized to meet specific weight and protection requirements. Paperboard offers a lighter-weight alternative for smaller, less fragile auto parts. Kraft paper provides a natural, eco-friendly option with good tear resistance. Additional options include foam inserts, which are often used in the automotive industry to provide superior cushioning. Choosing the right packaging material, such as cardboard packaging, ensures the safe delivery of automotive products, minimizing damage and maintaining the reputation of automotive brands.

Popular Automotive Packaging Solutions

Subscription Boxes for Auto Parts

The rise of e-commerce in the automotive industry has spurred innovation in auto parts packaging, with subscription boxes becoming increasingly popular. These customized packaging solutions cater to DIY enthusiasts and professional mechanics alike, delivering regularly needed automotive parts directly to their doorsteps. The auto parts boxes are typically designed to be durable and easy to open, enhancing the customer experience. Subscription boxes for automotive products often incorporate custom printed elements, reinforcing brand loyalty with each delivery. These high-quality automotive packaging boxes ensure that essential vehicle parts arrive in pristine condition, ready for immediate use. The packaging material used, often a sturdy corrugate, protects auto components from damage during shipping.

Custom Printed Packaging for Branding

In the competitive automotive industry, custom printed packaging, such as automotive product packaging boxes, is a powerful tool for enhancing brand recognition. Custom printed boxes allow automotive companies to showcase their logo, brand colors, and marketing messages, creating a memorable and professional impression. Using a CMYK printing method on a custom box ensures vibrant and eye-catching designs that stand out on store shelves or during delivery. Furthermore, custom packaging solutions can incorporate important product information, handling instructions, and QR codes for easy access to online resources. The strategic use of automotive packaging boxes as a branding tool, especially custom automotive packaging boxes, can significantly boost brand awareness and customer loyalty.

Innovative Packaging Design in the Automotive Sector

The automotive sector is witnessing a surge in innovative packaging design, driven by the need for improved protection, sustainability, and efficiency. New packaging solutions include eco-friendly packaging materials and box design innovations. Some automotive packaging incorporates sensors and tracking devices, providing real-time monitoring of the condition and location of automotive products during transit. These advancements in automotive packaging solutions are not only enhancing protection but also streamlining the supply chain and reducing costs for the automotive industry. Investing in these packaging boxes is a commitment to quality and innovation.

Designing Custom Automotive Boxes

Factors to Consider in Packaging Design

When designing custom automotive boxes, several factors must be carefully considered to ensure optimal protection and functionality. The size, shape, and weight of the auto part being packaged are paramount, influencing the choice of box style and the need for inserts. Environmental conditions during transit must be accounted for. Furthermore, branding and marketing considerations play a role in the box design, with custom printed elements enhancing visual appeal. Considering these factors will lead to an auto parts packaging solution that effectively protects and promotes automotive parts.

Use of Inserts in Auto Parts Packaging

Inserts play a crucial role in auto parts packaging, providing an added layer of protection and immobilization within the automotive boxes. By securely cradling the automotive parts within custom automotive packaging boxes, inserts minimize the risk of damage from shocks and vibrations. Inserts also allow for efficient organization and presentation of multiple components within a single box. The use of inserts is particularly beneficial for fragile or sensitive auto parts, ensuring they arrive in pristine condition. High-quality automotive packaging always considers custom inserts for optimal protection.

Kraft vs. Corrugate for Automotive Packaging

When selecting packaging materials for automotive boxes, the choice between kraft and corrugate depends on the specific needs of the automotive product and the level of protection required. Corrugate is a popular choice for its superior durability, making it ideal for heavier or more fragile auto parts. Kraft paper is better suited for lighter items or as an inner layer. The selection of the appropriate packaging material is essential for ensuring the safe delivery of automotive parts in the boxes for auto parts.

Support from Packaging Providers

Choosing the Right Packaging Partner

Selecting the right packaging partner is critical for ensuring the success of your custom automotive packaging efforts. Look for a provider with extensive experience and a proven track record of delivering high-quality packaging solutions. The ideal partner should offer a range of services, from design and prototyping to manufacturing and logistics, and be able to provide customized packaging solutions tailored to your specific needs. They should also be committed to sustainability and offer eco-friendly packaging options. By choosing a reliable and knowledgeable partner, you can streamline your packaging process and ensure your automotive products are well-protected.

Benefits of Working with a Custom Packaging Supplier

Working with a custom packaging supplier offers numerous benefits over using standard packaging. For example, when creating boxes for auto parts, a custom supplier offers advantages such as:

- Boxes precisely tailored to the dimensions of your auto parts, minimizing wasted space and reducing shipping costs.

- Specialized inserts to provide superior protection against shocks and vibrations.

Furthermore, a custom packaging supplier can enhance your brand visibility through custom printed boxes and creative box design, particularly with auto parts packaging boxes. By partnering with a custom packaging supplier, you can optimize your packaging process, improve product protection, and strengthen your brand identity within the automotive industry.

Case Studies: Successful Automotive Packaging Examples

Examining case studies of successful automotive packaging examples provides valuable insights into best practices and innovative solutions. One example involves a company that redesigned its auto parts packaging using a combination of corrugate and custom foam inserts, resulting in a significant reduction in product damage during transit with their new automotive product packaging. Another case study highlights a company that utilized custom printed boxes with QR codes to provide customers with easy access to installation guides and product information. These cases demonstrate the importance of tailored packaging solutions in the automotive industry. Such examples demonstrate the value of durable boxes and the advantages of using custom packaging solutions.