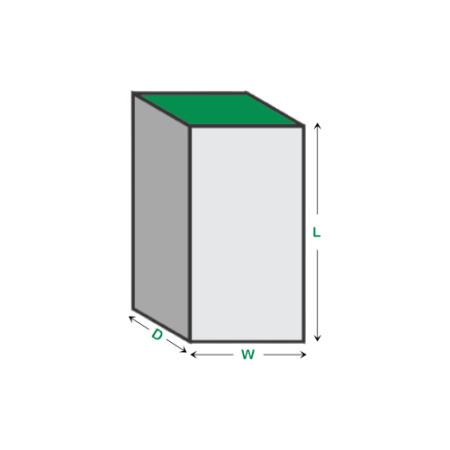

1-2-3 Bottom Box

The 1-2-3 bottom box is a secure and durable packaging solution for heavy and fragile items. Its interlocking bottom provides a sturdy base, while its simple design allows for quick and easy assembly without the need for adhesives.

1-2-3 Bottom Box

Custom 1-2-3 Bottom Boxes | Secure Snap-Lock Packaging

The 1-2-3 bottom box, also known as a snap-lock or interlock box, is an ingenious packaging solution that combines superior structural integrity with unparalleled ease of assembly. Its secure, interlocking bottom creates a sturdy foundation, making it an ideal choice for packaging small, heavy, or delicate items like electronics, glass bottles, and cosmetics.

Why Choose Our 1-2-3 Bottom Boxes

-

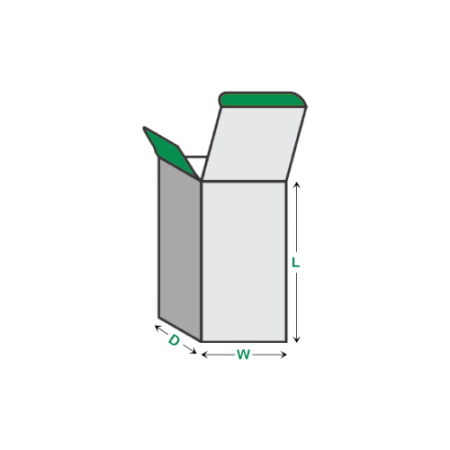

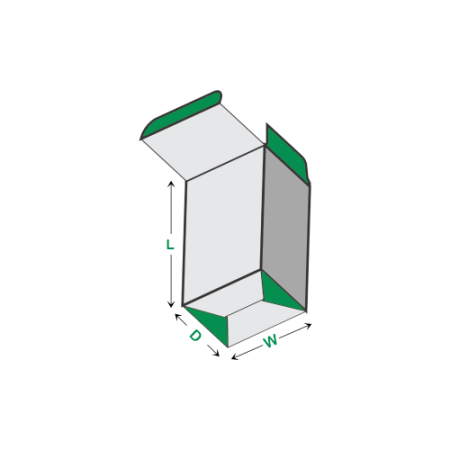

Superior Durability: The unique bottom closure features four interlocking flaps that form a strong base, preventing the box from giving way under the weight of the product.

-

No Adhesives Needed: The intuitive three-step assembly process requires no glue, tape, or special tools, saving you significant time and labor costs.

-

Versatile Design: This style is perfect for a wide range of industries, from retail and food to health & beauty and electronics, ensuring your products are always secure.

- Eco-Friendly Options: We offer a variety of sustainable materials, including recyclable Kraft paper and paperboard, allowing you to choose an environmentally conscious packaging solution.

-

Flat Shipping: Our boxes are shipped and stored flat, minimizing transportation costs and saving space in your warehouse.

Best Uses

-

Heavy or Fragile Items

-

Electronics & Tools

Popular Styles for Bottom Closure Boxes

Materials & Printing Options

-

Materials: Recycled Kraft, durable cardboard, and rigid paperboard.

-

Printing: CMYK, Pantone (PMS), and high-definition digital printing.

-

Finishes: Matte, gloss, foil stamping, Spot UV, and embossing.

Sustainability Focus

Our snap-lock boxes are made with recyclable and biodegradable stocks, aligning with your brand’s green mission. The adhesive-free assembly also simplifies the recycling process, providing an even more eco-friendly option for your packaging.

Related Products

How to Order

-

Request a Free Quote with your required dimensions, material, and quantity.

-

Approve the digital proof provided by our design team.

-

Production and printing take approximately 8–12 business days.

-

Enjoy free U.S. shipping and worldwide delivery.

FAQs – Custom 1-2-3 Bottom Boxes

Q: How is a 1-2-3 bottom box different from other box styles? A: Unlike a standard tuck-end box, the 1-2-3 bottom has interlocking flaps that create a sturdier base, making it ideal for heavier items.

Q: Do I need glue or tape to assemble the box?

A: No, the snap-lock design is self-locking and does not require any adhesives to stay secure.

Q: Are these boxes easy to assemble?

A: Yes, they are named for their simple, three-step assembly process that can be done quickly by hand.

Q: What is the minimum order quantity (MOQ)?

A: Our MOQ for custom 1-2-3 bottom boxes starts at just 100 units.

Elevate your brand with 1-2-3 bottom boxes that offer unmatched security and simplicity.

| 1 |

Available in all custom sizes |

|---|---|

| 2 |

CMYK, PMS, Foiling, Spot UV, Embossing, Plastic Window. |

| 3 |

10pt to 28pt (60lb to 400lb) Kraft, Eco Friendly, E-flute. |

| 4 |

Starts from 100 boxes. |

| 5 |

Gloss/Matte/Uncoated. |

| 6 |

Die cutting, pasting, perforation. |

| 7 |

Digital Proof With 2D & 3D view. |

| 8 |

Fastest Turnaround time. |