The Ultimate Guide to Mailer Box Size

2025-08-08 07:30:04

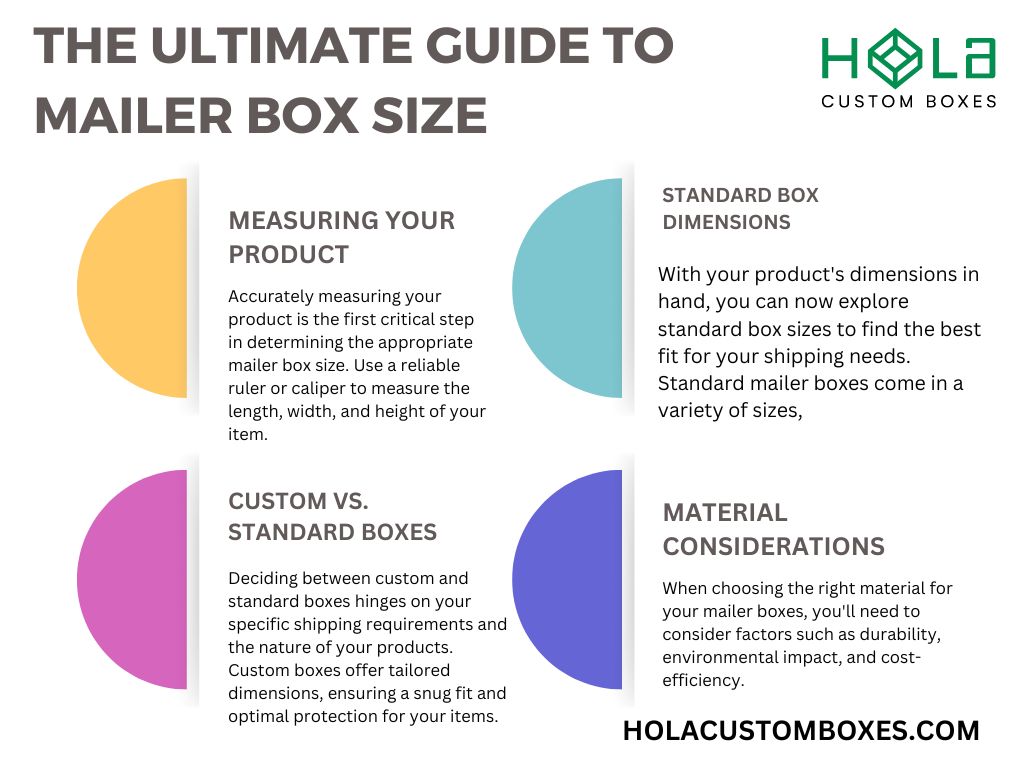

Choosing the right mailer box size is crucial for product protection and minimizing shipping costs. Measure your products accurately, accounting for any additional packaging materials. Standard box sizes such as small (6" x 4" x 3"), medium (12" x 9" x 4"), and large (18" x 12" x 6") can cover most needs. Custom boxes offer a snug fit but come with higher costs and lead times. Material choice, like corrugated cardboard or eco-friendly options, impacts durability and sustainability. Balance weight and durability based on your products' needs. For optimal protection and cost-efficiency, understanding these variables is key to the ultimate mailer box solution.

Key Takeaways

- Accurate Product Measurement: Measure the length, width, and height of your product including packaging materials for a precise fit.

- Standard Box Dimensions: Choose from small, medium, or large standard sizes to ensure cost-efficiency and product protection.

- Custom vs. Standard Boxes: Weigh the benefits of custom boxes for a snug fit against the cost-effectiveness and availability of standard boxes.

- Material Selection: Select appropriate materials like corrugated cardboard or kraft paper based on durability needs and sustainability goals.

- Weight and Durability: Match the box's weight capacity and structural integrity to your product's weight and shipping conditions.

Importance of Mailer Box Size

Choosing the correct mailer box size is crucial for ensuring product protection and minimizing shipping costs. When you select a well-fitted box, it reduces the risk of damage during transit, maintaining your product's integrity.

Additionally, a properly sized box minimizes the need for excess packaging materials, which cuts down on both material costs and environmental impact.

Incorrect sizing can lead to higher shipping fees due to dimensional weight pricing, where carriers charge based on the package dimensions rather than its actual weight. Moreover, oversized boxes may shift during transport, increasing the likelihood of damage.

How to Measure Your Product Accurately

Getting the right mailer box size starts with precise product measurements. Use a reliable measuring tool like a ruler or caliper to determine the length, width, and height of your product. Be sure to include the longest dimensions, accounting for any protrusions, handles, or irregular shapes. Record these measurements in either inches or centimeters, depending on the preference or requirements of your box manufacturer.

Factoring in Packaging Materials

In addition to the product size, consider any protective packaging you plan to use, such as bubble wrap, foam inserts, or padding. Add the thickness of these materials to your initial measurements to ensure a proper fit. A snug-fitting box minimizes internal movement during shipping, reducing the risk of damage. Always double-check your dimensions to prevent costly errors and ensure your packaging is both protective and cost-efficient.

Standard Box Dimensions

With your product's dimensions in hand, you can now explore standard box sizes to find the best fit for your shipping needs. Standard mailer boxes come in a variety of sizes, ensuring that you can select one that maximizes space efficiency and product protection.

Here are three commonly used standard box dimensions:

Small (6' x 4' x 3'): Ideal for compact items such as cosmetics, small electronics, or accessories.

Medium (12' x 9' x 4'): Suitable for clothing, books, or larger gadgets.

Large (18' x 12' x 6'): Best for bulkier products like household items, multiple smaller products, or larger apparel.

Understanding these standard dimensions helps you choose the right packaging, reducing material waste and shipping costs.

Custom Vs. Standard Boxes

Deciding between custom and standard boxes hinges on your specific shipping requirements and the nature of your products. Custom boxes offer tailored dimensions, ensuring a snug fit and optimal protection for your items. They can reduce shipping costs by minimizing excess space, which also helps in adhering to dimensional weight pricing standards. However, custom boxes usually involve higher initial costs and longer lead times.

Standard boxes, on the other hand, are readily available and cost-effective. They're ideal for businesses with uniform products or less stringent packaging needs. While they mightn't offer a perfect fit, they streamline the procurement process and reduce lead times.

Evaluate the trade-offs between customization costs and the benefits of a precise fit to determine the best option for your needs.

Material Considerations

When choosing the right material for your mailer boxes, you'll need to consider factors such as durability, environmental impact, and cost-efficiency. Selecting the appropriate material can directly affect the performance and sustainability of your packaging solution.

Here are three key material considerations:

Corrugated Cardboard: Offers high durability and protection, making it suitable for heavy or fragile items. It's recyclable and cost-effective.

Kraft Paper: Known for its eco-friendliness and biodegradability. It's ideal for lightweight items but offers less protection compared to corrugated cardboard.

Chipboard: Lightweight and cost-efficient, best for items that don't require heavy-duty protection. It's less durable and not as environmentally friendly as other options.

Carefully evaluating these materials ensures your mailer boxes meet your specific needs.

Weight and Durability

Understanding the relationship between the weight and durability of your mailer boxes is crucial to ensuring that your packaging solution meets the demands of your shipping needs. Heavier items require boxes made from stronger materials like corrugated cardboard to prevent damage during transit. You need to balance the box's weight with its durability to avoid unnecessary shipping costs.

Opt for double-walled or reinforced designs for extra protection. Always check the box's weight capacity to match it with your product's weight. Durability isn't just about strength; it's also about maintaining structural integrity under various conditions, such as humidity and stacking pressure.

Fragile Item Protection

Properly protecting fragile items in your mailer boxes requires meticulous attention to cushioning materials and packing techniques to ensure they arrive safely at their destination. You need to consider multiple factors to safeguard your items effectively.

Bubble Wrap: Use multiple layers of bubble wrap around each fragile item. Ensure the bubbles face inward to maximize shock absorption.

Foam Inserts: Custom-cut foam inserts provide tailored protection, minimizing movement and distributing impact forces evenly.

Packing Peanuts: Fill void spaces with packing peanuts to prevent shifting during transit. Ensure they surround the item entirely for optimal cushioning.

Adopting these methods ensures that your fragile items are well-protected, significantly reducing the risk of damage during shipping. Always double-check your packing techniques to maintain the highest standards of safety.

Cost-Effective Shipping

To achieve cost-effective shipping, you must optimize both the size and weight of your mailer boxes while maintaining adequate protection for the contents.

Start by selecting a box that fits your product snugly, reducing excess space that could lead to higher dimensional weight charges. Use lightweight yet durable materials to minimize the box's weight without compromising strength.

Accurately measure your items and select the smallest possible box that still offers sufficient cushioning. Consider flat-rate shipping options if they align with your package dimensions.

Efficiently packing multiple items in one box can save costs by reducing the number of shipments. Lastly, always balance cost reduction with the necessity of protecting the items during transit to avoid additional expenses from damages.

Environmental Impact

While optimizing for cost-effective shipping, you should also consider the environmental impact of your mailer box choices. Focusing on eco-friendly options can minimize your carbon footprint and promote sustainable practices.

Ensure that your mailer boxes meet the following criteria:

Material Selection: Choose recycled or biodegradable materials to reduce waste. Cardboard and paperboard are excellent options.

Size Efficiency: Opt for appropriately sized boxes to eliminate excess packaging, which reduces material usage and shipping emissions.

Reusability: Select durable boxes that can be reused multiple times, extending their lifecycle and reducing the need for new materials.

Branding and Presentation

Incorporating your brand's identity into the design of your mailer boxes enhances customer experience and reinforces brand recognition. Start by choosing colors that match your brand palette. Use high-quality printing to display your logo and tagline prominently. Don't forget to include any brand-specific patterns or imagery that resonate with your target audience.

The interior of the box should also reflect your branding—consider custom tissue paper or stickers. Precision in design is crucial; ensure all elements are aligned and clear. Additionally, think about the unboxing experience. Adding a personalized thank-you note or a branded insert can make a significant impact.

Consistency in branding across all packaging elements solidifies your brand's presence and leaves a lasting impression.

Conclusion

Choosing the right mailer box size is crucial for efficient shipping and product protection. Did you know that reducing your packaging size by just 10% can lower shipping costs by up to 25%?

Measure your items precisely, and consider custom boxes for a perfect fit. Always factor in material strength and environmental impact.

By optimizing your packaging, you'll enhance your brand's presentation while being cost-effective and eco-friendly. Your attention to detail pays off significantly.