What Is Custom Packaging and Why It Matters?

2025-09-25 13:05:59

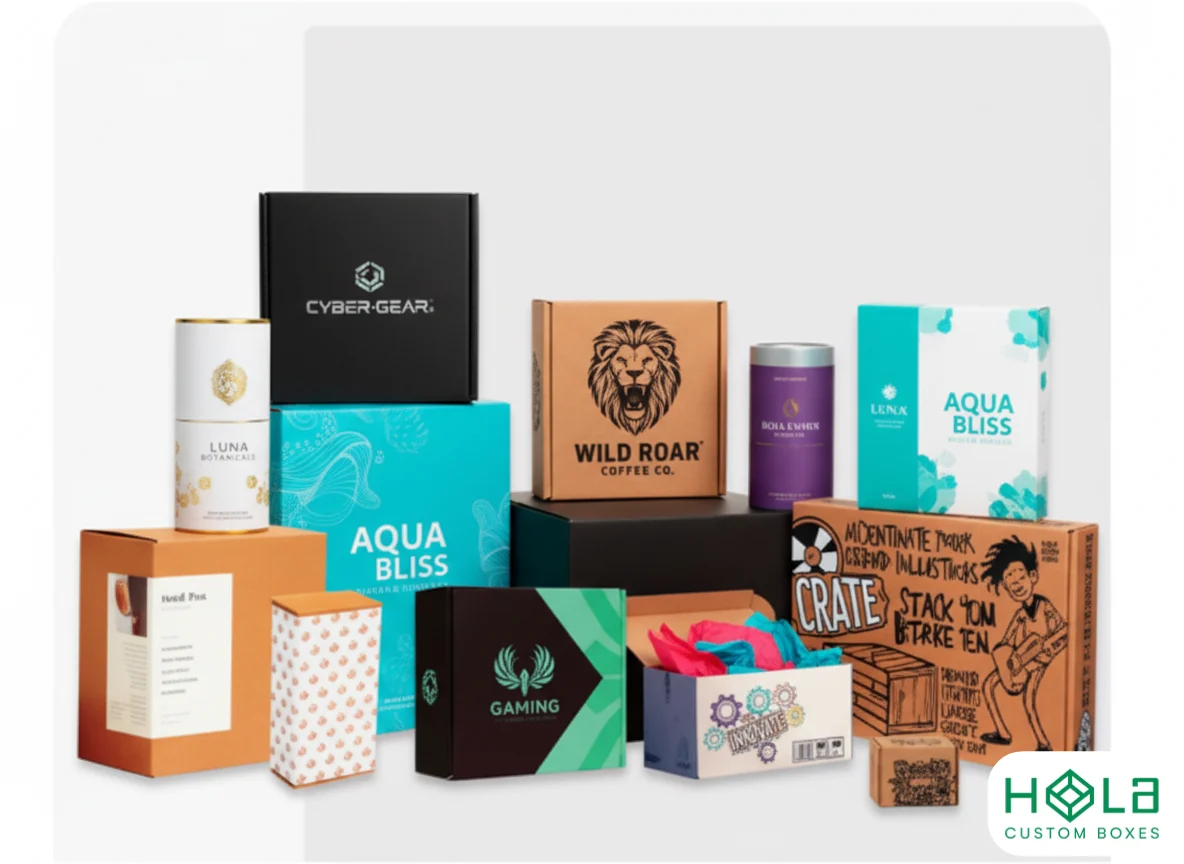

What Is Custom Packaging and Why It Matters

Custom packaging is a performance tool—not just a box—that you design around your product, user, and supply chain. Done right, it lifts brand recall 3–7% and CTR 5–12%, cuts damage up to 40%, and trims freight costs 10–25% via right-sizing and mono-materials. You’ll speed fulfillment (15–30 seconds per pick), meet sustainability targets, and pass ISTA/CR needs. Prioritize easy-open ergonomics, recyclable substrates, and data-driven dielines. Keep going to see how to apply it step by step.

Main Points

- Custom packaging is brand-specific design of boxes and inserts that protect, present, and ship products more effectively than generic packaging.

- It drives measurable marketing lift, improving brand recall 3–7% and click-through rates 5–12% through rapid, consistent visual branding.

- Engineered fits and right-sizing reduce damage up to 40% and cut DIM weight and freight costs by 10–25%.

- User-centered and sustainable specs improve unboxing and compliance, targeting 10–20% material reduction with recyclable mono-materials.

- Optimized dielines and standardized SKUs speed fulfillment, saving 15–30 seconds per pick and lowering reverse logistics costs.

6 Principles of Custom Packaging Design

Although aesthetics grab attention, effective custom packaging starts with measurable principles: user-centered structure, material optimization, brand signal clarity, and supply-chain efficiency.

You prioritize ergonomics, easy-open features, and protective geometry validated by drop and compression tests.

Apply sustainable packaging design by right-sizing, reducing material layers, and specifying recyclable mono-materials; target a 10–20% weight reduction without compromising ISTA performance.

Use data to tune dielines for pack density and reduce dimensional weight fees.

Guarantee custom packaging with logo communicates recall in three seconds: high-contrast marks, compliant color profiles, and scalable print methods.

Standardize SKUs and pallet patterns to cut handling time and logistics emissions.

For tailored advice and rapid turnaround, contact Hola Custom Boxes via rush order options or phone support at (214) 613-5725.

Real-World Use Cases of Custom Packaging Solutions

Where do custom packaging solutions prove their value?

You’ll see measurable gains across regulated, fragile, and high-velocity categories. Pharmaceuticals use tamper-evident, serialized cartons that cut diversion risk by up to 70%.

Electronics brands deploy ESD-safe trays and right-sized inserts, reducing transit damage below 0.5%.

Meal kits rely on phase-change liners that hold 0–4°C for 48 hours, lowering spoilage 18–25%.

DTC cosmetics use custom retail packaging with drop-tested fiberboard, trimming DIM weight 12–20%.

Industrial parts adopt color-coded kitting to slash pick errors 30%.

Partnering with custom packaging services lets you optimize cube utilization, automation readiness, and compliance at scale.

Our rush order options enable fast turnaround for urgent packaging needs without compromising quality.

Improved Branding and Customer Experience

Even before a product is unboxed, custom packaging sets expectations, hardwires recall, and lifts conversion. You control first impressions with calibrated typography, Pantone-matched inks, and material finishes that signal value.

Studies show consistent branding can lift revenue 10–20%; custom logo packaging boxes amplify that consistency across channels, boosting aided recall and repeat purchase.

Consistent branding lifts revenue 10–20%; custom logo packaging boosts recall and repeat purchases across channels.

Engineer frictionless unboxing with right-sized inserts, easy-open tear strips, and scannable QR codes that drive post-purchase engagement.

For beauty, custom cosmetic packaging optimizes shelf impact via color harmony, tactile coatings, and sustainable substrates without compromising barrier performance.

Result: higher NPS, lower return rates, and measurable LTV growth.

Additionally, brands can strengthen sustainability and aesthetics by choosing eco-friendly materials like recyclable cardboard or kraft paper, paired with premium finishes such as matte, gloss, or UV coating to elevate presentation.

Perks of Customizing Your Product Packaging

You’ve optimized branding and unboxing; now customization delivers measurable advantages across cost, performance, and growth.

By right-sizing custom boxes and packaging, you cut DIM weight, reduce filler up to 40%, and lower freight 8–20%.

Engineered structures raise compression strength, minimizing damage rates below 1%.

Barcode, lot, and QR versioning streamline fulfillment and traceability, shaving seconds per pick.

Material mapping lets you substitute substrates to hit EPR, PCR, and curbside criteria without compromising protection.

Modular dielines accelerate SKUs, shorten lead times, and stabilize inventory.

The benefits of custom packaging compound: fewer returns, faster packing, cleaner data, and scalable, defensible unit economics.

Custom fold-and-assemble designs add speed and branding by being easy to store and assemble, and can be customized with logos and brand colors for enhanced visibility.

What are the Benefits of Custom Packaging?

Precision pays. You cut damage rates by up to 40% with engineered fits, right-size materials, and verified burst/ECT ratings.

Precision pays: engineered fits and right-size materials cut damage rates by up to 40%.

You lift conversion because custom packaging boxes with logo boost brand recall by 80% and increase repeat purchase intent. You reduce DIM weight and freight by 10–25% through optimized cube efficiency and lighter substrates.

You streamline fulfillment: scannable layouts, kitting, and easy-open features shave 15–30 seconds per pick-pack.

You meet compliance with recyclable inks and FSC or SFI fibers. Choose sustainable custom packaging to cut Scope 3 emissions, validate claims with LCA data, and qualify for retailer scorecards—while lowering total landed cost.

Eco-conscious shoppers favor brands using recyclable materials, and clearly communicating these choices can enhance loyalty and reduce returns through better-protected, right-sized packaging.

Trendy Packaging Styles for Small Businesses

From mailer boxes with peel-and-seal closures to molded-pulp inserts, small businesses are adopting packaging styles that convert and cut cost.

You’ll see data-backed wins: right-sized corrugate reduces DIM weight up to 18%, and paper-based void fill cuts damage rates by 22%.

For unboxing, print-on-brown kraft, belly bands, and QR-enabled stickers drive repeat purchases.

Consider compostable films, glassine bags, and mono-material pouches for recyclability.

Magnetic rigid mailers elevate cosmetic packaging for small business without freight penalties.

Ship-in-own-container designs slash packaging steps.

Partner with custom packaging companies for dieline optimization, FSC sourcing, and digital print runs that enable rapid A/B testing.

Hola Custom Boxes supports these strategies with eco-friendly materials and custom finishes like Spot UV, embossing, and recyclable kraft to align performance with sustainability.

3 Fundamental Types of Custom Packaging

While materials and graphics grab attention, the core decision is which packaging architecture best fits your product, supply chain, and sustainability goals.

Choose packaging architecture first—it aligns product, logistics, and sustainability for performance beyond materials and graphics.

You’ll benchmark options by protection, cube efficiency, assembly speed, and recyclability. Selecting the right form lowers damages 10–30%, cuts freight up to 18%, and accelerates pick-pack.

- Rigid set-up boxes: premium feel, crush-resistant; higher cost, low flat-pack efficiency.

- Folding cartons: lightweight, print-rich, 80–90% board yield; ideal for custom packaging boxes wholesale.

- Corrugated mailers/shipper boxes: ISTA-ready, low DIM weight, quick-tape closure.

- custom display packaging boxes: PDQ counter trays and shelf-ready packs that convert from shipper to fixture, boosting sell-through.

To align with sustainability and branding goals, consider that retail boxes can be made from eco-friendly materials with personalized graphics and custom sizes tailored to your product.

Stand Out From the Competition

With your packaging architecture locked, differentiation becomes a measurable advantage, not just a creative exercise. You win shelf space and search share by quantifying impact: aim for a 3–7% lift in unaided recall via high-contrast palettes, and a 5–12% CTR increase using scannable QR plus GS1 barcodes.

Engineer custom food packaging boxes with logo using Pantone-matched inks, 300+ DPI micro-patterns, and tactile varnishes to raise dwell time. Optimize retail display packaging with eye-tracking data: place hero claims in the upper-left visual hotspot, 30–45°-angled facings, and 8–12 ft legibility.

A/B test dielines, materials, and finishes; promote the winner. Additionally, leverage eco-friendly materials to appeal to environmentally conscious consumers and enhance brand reputation.

What are the benefits of custom packaging?

Because packaging is a performance lever—not just a container—you gain measurable advantages with custom solutions: 3–7% lifts in unaided brand recall via distinct color systems, 5–12% CTR increases through QR + GS1 integration, and higher dwell time using tactile coatings and micro-patterns.

Packaging is a performance lever: boost recall 3–7%, lift CTR 5–12%, increase dwell with tactile cues.

You’ll also cut waste by right-sizing materials and optimize logistics with cube efficiency.

- Engineer fit-for-purpose structures that reduce breakage rates and reverse logistics costs.

- Use wholesale custom packaging to scale SKUs while maintaining brand consistency and unit economics.

- Deploy affordable custom packaging to test variants via short runs and digital print.

- Instrument packaging with track-and-trace to improve forecast accuracy.

Custom stationery boxes are made from 100% recyclable materials and offer diverse printing and finishing options that strengthen brand identity while supporting sustainability.

What are the 5 importance of packaging?

Packaging shows up as a measurable growth lever, so it’s worth framing its five core roles: protection, communication, conversion, efficiency, and sustainability.

You reduce damage rates with engineered structures, validated by ISTA drop and vibration tests, protecting margin and CX.

You communicate value through packaging and labeling: clear claims, barcodes, dates, and instructions increase trust and decrease returns.

You convert by optimizing unboxing UX—color, typography, and form boost recall and basket size.

You drive efficiency with right-sizing that lowers DIM weight and speeds fulfillment.

You guarantee sustainability via recyclable substrates and LCA metrics—while meeting packaging compliance to avoid fines and delays.

Eco-conscious brands can also leverage eco-friendly boxes made from recyclable cardboard and paper to reduce energy use and enhance brand visibility.

Who needs custom packaging?

If you sell a physical product and care about margin, CX, or compliance, you need custom packaging.

You need it when unit economics hinge on dimensional weight, damage rate, and unboxing satisfaction scores.

It’s essential if you operate in regulated categories—think custom pharmaceutical packaging with lot tracking, tamper evidence, and FMD/DSCSA-ready barcodes—or brand-sensitive segments like custom makeup packaging with shade accuracy, inserts, and retail planogram fit.

- Reduce breakage 30–60% with engineered cushioning.

- Cut freight 8–15% via right-sized cartons.

- Boost conversion 5–12% using branded, tactile substrates.

- Accelerate compliance audits with serialized labels and validated materials.

Curious if custom packaging fits your brand?

Wondering whether custom packaging is worth it for your brand? Start with fit: product fragility, regulatory labeling, unboxing speed, and shipping cost.

If you sell premium goods, technical packaging ROI is measurable. Brands adopting dielines tailored to SKU dimensions cut void fill by 18–32% and reduce damages by up to 40%.

For regulated goods, custom CBD packaging guarantees ASTM child-resistance, tamper evidence, and CFR-compliant panel space.

Beauty brands gain precision inserts for shade integrity and print profiles that elevate cosmetic packaging boxes.

Calculate CAC/LTV lift from improved shelf impact and returns reduction. If gains exceed per-unit uplift, proceed.

Do customers really care about custom packaging?

Those ROI models only matter if buyers notice—and they do. You’re competing in the unboxing moment where 64–80% of shoppers report packaging influences purchase and repeat intent.

Custom soap packaging, for example, lifts perceived product purity and value. Clear packaging symbols and meanings reduce friction, returns, and compliance risk, improving margins.

- Reduce cognitive load: standardized icons cut decision time by ~20%.

- Increase conversion: premium substrates and finishes can boost add-to-cart rates 5–12%.

- Lower damage: engineered inserts drop breakage by 30–40%, protecting LTV.

- Amplify shareability: print and QR touchpoints raise UGC rates 2–4x, feeding efficient acquisition.

Do you want your brand to stand out vividly in your customers’ minds?

How do you encode your brand so customers recall it in under 200 milliseconds—the average time visual memory forms? You engineer salience. Use high-contrast palettes, distinctive geometry, and repeatable motifs that score high on visual search efficiency.

Apply measurable heuristics: 3–5 color palette, 45–60% negative space, and typography with x-height ratios optimized for distance legibility.

Translate this to custom action figure packaging: window-to-box ratio >40% to showcase detail, Pantone-matched accents, and QR-linked AR reveals to boost dopamine-driven recall.

Track lift via aided recall surveys and CTR. For luxury candle packaging design trends, specify textured substrates, foil micro-emboss patterns, and FSC-certified rigid boxes with magnet closures.

Does Custom Packaging Really Matter?

Why does custom packaging matter? You’re optimizing performance, not just looks. Data shows packaging drives trial, retention, and margin.

Engineering materials, structure, and print specs boosts protection, compliance, and shelf impact—critical for custom cartridge packaging and edible gummy packaging where freshness, labeling, and tamper evidence affect conversions and risk.

- Increase sales: Distinct dielines and CMYK/spot color systems lift recognition; A/B tests show up to 30% CTR gains on shelves.

- Reduce damage: Right-size corrugate and inserts cut breakage 20–40%.

- Accelerate compliance: Child-resistant features and FDA/FTC labeling prevent penalties.

- Lower costs: SKU-optimized runs reduce waste 10–25% via material efficiency.

How can I find custom boxes online?

Looking for custom boxes online starts with narrowing vendors by capabilities, not slogans: filter for dieline engineering, minimum order quantities (MOQs), substrate range (FSC paperboard, E-flute/B-flute corrugate), print processes (digital, offset, flexo), and color control (G7, Pantone spot).

Then audit proofs: demand 300–600 dpi print samples, ΔE color reports, and edge-crush/burst test data. Verify structural CAD support and ship-testing (ISTA 3A).

Audit proofs rigorously: highdpi samples, ΔE color reports, ECT/burst data, CAD validation, and ISTA 3A shiptesting.

Compare unit economics across MOQs, tooling, and freight. For custom cart packaging or cartridge packaging, confirm child-resistant (CR) certifications where required. Assess lead times, on-time delivery rates, and defect PPM.

Prioritize portals offering online quotes, instant dielines, and trackable revisions.

Want to go even more eco-friendly, and don’t mind sacrificing on color?

If you can trade saturated color for sustainability gains, shift to mono-material, fiber-first specs: uncoated FSC-certified kraft or 100% PCW chipboard, water- or soy-based inks at ≤200% TAC, and no laminate films.

You’ll cut VOCs, simplify MRF sorting, and boost recycling yields by up to 20%. CR packaging and edibles packaging both benefit from fewer mixed substrates and compliant ink sets.

- Specify 18–24 pt chipboard; target 350–450 gsm basis weight.

- Use one-color line art; avoid heavy solids above 30% coverage.

- Swap plastic windows for die-cuts.

- Replace spot UV with aqueous dispersion varnish (recyclable).

Conclusion

You’ve seen how custom packaging boosts brand recall, increases perceived value, and lifts conversion rates. By applying the six design principles, leveraging real-world use cases, and optimizing materials, you’ll cut damage rates, reduce shipping costs, and improve unboxing satisfaction. Data shows tailored boxes can raise repeat purchases and social shares. Choose eco-friendly substrates if you can trade saturated color for recyclability. Ready to stand out? Source custom boxes online with dieline support, short runs, and fast prototyping.