What Is Aqueous Coating on Custom Packaging

2025-08-11 07:22:45

Aqueous coating is a water-based varnish applied to custom packaging to enhance its appearance, durability, and protection. It offers a range of finishes, including gloss, matte, satin, and soft-touch options, making it an eco-friendly and versatile solution. This coating provides a durable barrier against scratches and scuffs, while amplifying the visual appeal of printed materials. With its ability to enhance color vibrancy and provide a refined appearance, aqueous coating is a popular choice for elevating brand image. As we explore the world of custom packaging, the benefits and applications of aqueous coating become even more apparent.

Main Points

• Aqueous coating is a water-based varnish applied to custom packaging for enhanced appearance, durability, and protection against scratches and scuffs.

• It's an eco-friendly option available in various finishes, including gloss, matte, satin, and soft touch, to suit different packaging needs and brand images.

• The coating process involves applying a thin layer of transparent varnish, which is rapidly dried to provide a refined appearance and protection.

• Aqueous coating amplifies color vibrancy, provides a durable barrier, and is suitable for products that undergo handling, making it ideal for packaging materials.

• This coating type is distinct from UV coating, offering matte or satin finishes and eco-friendliness, whereas UV coatings provide high-gloss finishes and scuff resistance.

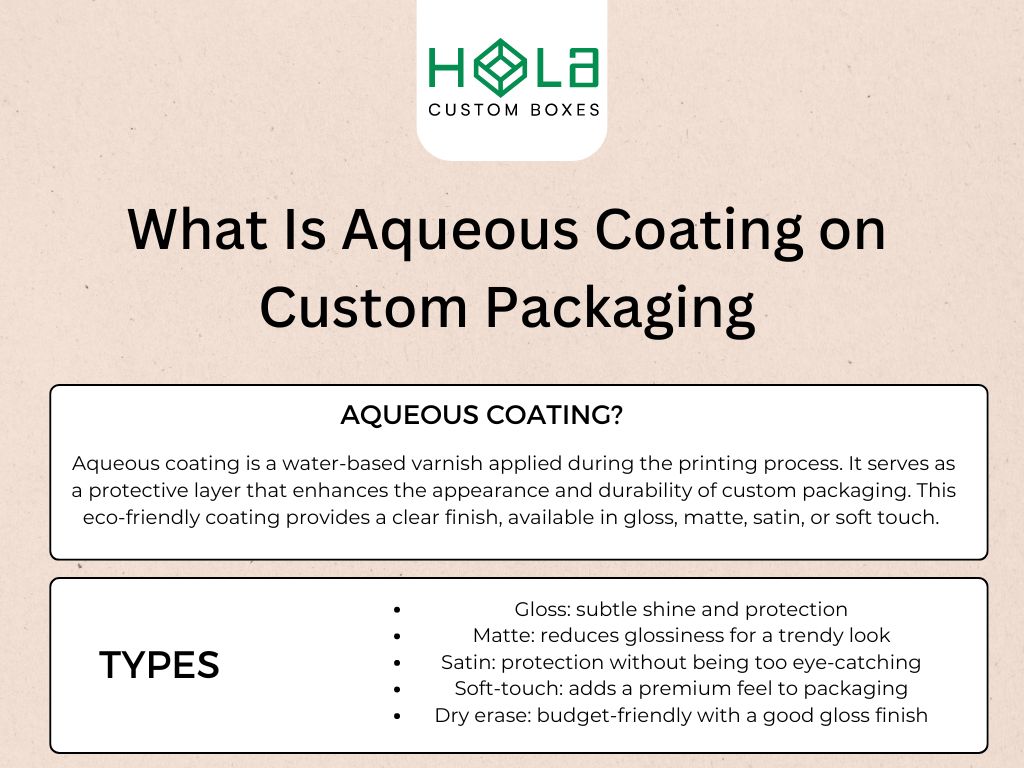

Understanding Aqueous Coating

Aqueous coating is a water-based varnish applied during the printing process to enhance both the durability and visual appeal of custom packaging. This eco-friendly option offers a clear finish in gloss, matte, satin, or soft touch, creating a polished and professional look. It acts as a protective layer, shielding the surface from scratches, scuffs, and other handling damage.

Benefits for Packaging Longevity and Brand Appeal

By adding a double layer of protection, aqueous coating not only elevates the packaging’s appearance but also extends its lifespan. This makes it a preferred choice for businesses aiming to maintain product integrity while reinforcing a premium brand image through high-quality, sustainable packaging solutions.

Types of Aqueous Coatings

Coating finishes for custom packaging encompass a range of options, each tailored to achieve a specific aesthetic and functional effect.

The types of aqueous coatings include:

Gloss: subtle shine and protection

Matte: reduces glossiness for a trendy look

Satin: protection without being too eye-catching

Soft-touch: adds a premium feel to packaging

Dry erase: budget-friendly with a good gloss finish

The Aqueous Coating Process

Transparent and water-based varnish is applied to custom packaging to achieve a refined appearance and enhanced protection.

The aqueous coating process involves applying a thin layer of water-based coating to the printed material, followed by rapid drying through a heated system.

This process provides a glossy finish, protection, and durability to custom packaging, making it ideal for products that undergo handling.

Benefits of Aqueous Coating

One of the primary advantages of utilizing aqueous coating on custom packaging is its ability to amplify visual appeal while providing a durable barrier against environmental elements.

This environmentally friendly coating offers numerous benefits, including:

- Enhanced color vibrancy and glossy or matte finishes

- Compatibility with various printing methods, including offset and digital printing

- Protection against moisture and abrasion

- Versatility for different packaging needs and materials

- Elevated appearance for brochures, flyers, business cards, and more

Aqueous Vs UV Coating

In the pursuit of ideal packaging protection and visual appeal, two popular coating options emerge: aqueous and UV coating, each with distinct characteristics and advantages.

Aqueous coating, a water-based AQ coating, offers eco-friendly and matte or satin finishes, suitable for minimal handling.

UV coatings, on the other hand, provide a high gloss finish, depth, and richness, making them ideal for products requiring durability and resistance to scuffing.

How to Apply Aqueous Coating

Most custom packaging materials require thorough preparation before applying an aqueous coating to guarantee a smooth and even finish.

To apply aqueous coating:

Apply the coating before ink printing on custom packaging materials.

Dry the coating quickly through a heated process to secure a smooth finish.

Take care during application to prevent warping, wrinkling, or curling of the packaging material.

Ensure proper application to achieve a durable and professional finish.

Apply the coating to enhance the appearance of custom packaging and protect it from scratches and scuffs.

Choosing the Right Coating

With the application process complete, the next step is to select the most suitable aqueous coating that aligns with the desired visual and functional requirements of the custom packaging.

Choose the best AQ coating that works best for your printing and packaging needs, considering the target audience and desired finish. Types of aqueous coatings, such as gloss or matte, can resist fingerprints and provide a unique aesthetic, making it essential to choose the right coating method that meets your goals.