Understanding the Different Types of Cardboard and Corrugated Boxes: An Essential Guide for Packaging Needs

2025-08-11 07:57:24.jpg)

Corrugated cardboard encompasses a diverse array of grades, types, and styles. Common types include SBS, CUK, UUK, CRB, and FBB, with varying composition, strength, and surface finishes. Key corrugated box styles like slotted, telescope, rigid, and self-erecting boxes cater to diverse packaging needs. Flute profiles (A, B, C, E, F) determine the cardboard's structural integrity and cushioning properties.

Manufacturers - https://holacustomboxes.com continue to innovate designs like chipboard and honeycomb, expanding the versatility of this essential packaging material. Responsible disposal and recycling are paramount, requiring systematic collaboration with waste management companies. Further exploration reveals the nuances underlying the composition and applications of corrugated cardboard.

Main Points

- Common types of cardboard include SBS, CUK, UUK, CRB, and FBB, each with distinct compositions, strengths, and surface finishes.

- Key corrugated box styles include slotted boxes, telescope boxes, rigid (Bliss) boxes, self-erecting boxes, and folders for diverse packaging needs.

- Cardboard structures consist of linerboard and fluted medium, with flute profiles (A, B, C, E, F) determining strength and cushioning properties.

- Cardboard recycling involves systematic collaboration with waste management companies and preparing boxes by removing packing materials and flattening.

- Industrial environments often use cardboard balers for efficient storage and transportation of cardboard to recycling facilities.

Composition of Corrugated Cardboard Boxes

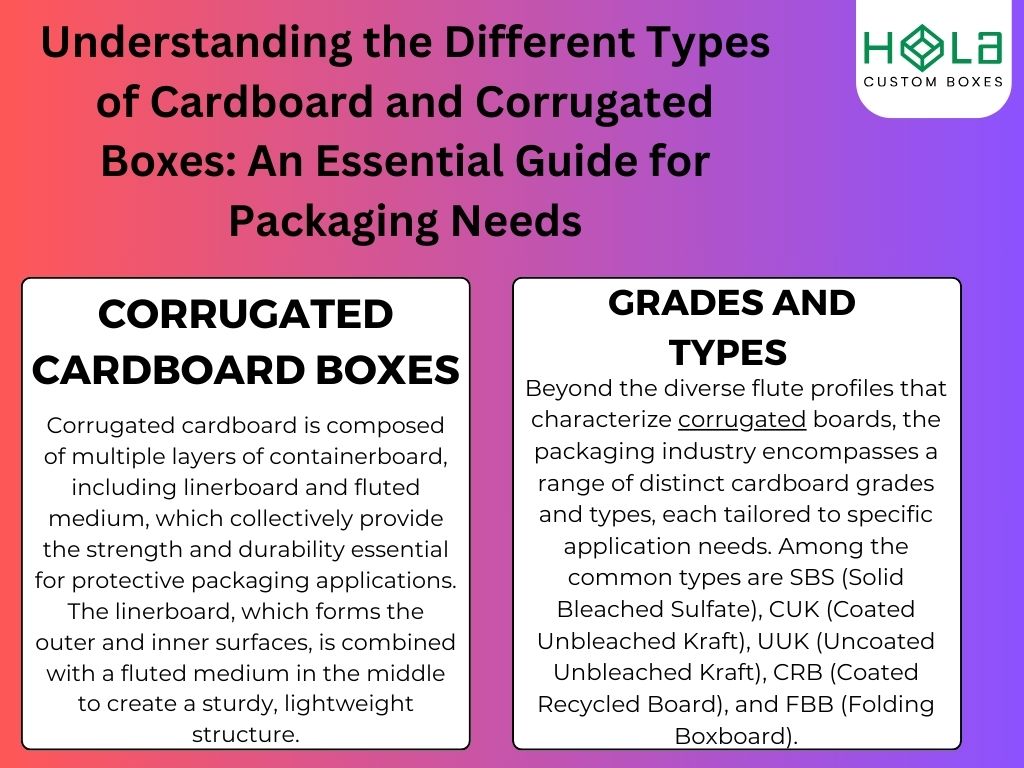

Corrugated cardboard is composed of multiple layers of containerboard, including linerboard and fluted medium, which collectively provide the strength and durability essential for protective packaging applications. The linerboard, which forms the outer and inner surfaces, is combined with a fluted medium in the middle to create a sturdy, lightweight structure.

Depending on the number of layers, corrugated boards can be classified as Single Face, Single Wall, Double Wall, or Triple Wall, each offering varying levels of protection and performance capabilities. The specific flute profile, such as A, B, C, E, or F, determines the strength and cushioning properties of the corrugated cardboard, allowing for customization based on the packaging requirements.

Implement Real-Time Tracking Systems

For small businesses, integrating real-time tracking systems can significantly improve delivery transparency and operational efficiency. These systems offer live updates on package location and delivery status, enabling quick responses to any logistical challenges.

By leveraging GPS technology, businesses can accurately track delivery vehicles and shipments, ensuring on-time arrivals and reducing the risk of lost or delayed orders. Customers benefit from precise ETAs and continuous updates, fostering trust, improving satisfaction, and enhancing the overall delivery experience.

Grades and Types of Cardboard

Beyond the diverse flute profiles that characterize corrugated boards, the packaging industry encompasses a range of distinct cardboard grades and types, each tailored to specific application needs. Among the common types are SBS (Solid Bleached Sulfate), CUK (Coated Unbleached Kraft), UUK (Uncoated Unbleached Kraft), CRB (Coated Recycled Board), and FBB (Folding Boxboard). These cardboard grades differ in their composition, strength, and surface finishes, making them suitable for diverse packaging requirements, from shipping boxes to product displays.

Manufacturers continuously innovate new cardboard designs, such as chipboard, honeycomb, and gray paperboard, to meet the evolving needs of industries ranging from e-commerce to food packaging. The versatility of cardboard ensures its enduring prominence in the world of packaging solutions.

Key Corrugated Box Styles

Encompassing a diverse array of specialized designs, corrugated box styles cater to the myriad packaging needs across industries, from shipping and storage to point-of-purchase displays.

The ubiquitous slotted boxes, including RSC, HSC, OSC, and FOL variations, offer versatile and sturdy solutions.

Telescope boxes, with their top and bottom pieces that fit together, provide secure packaging, while rigid (Bliss) boxes, with their two-panel design and folding body, deliver exceptional durability.

Self-erecting boxes, featuring regular slotted container or telescope-style tops, enable easy and efficient assembly.

Folders, made of one or more combined board pieces, come in popular styles like OPF and FPF, catering to diverse presentation and display requirements.

Cardboard Recycling and Standards

With the vast array of corrugated box styles catering to diverse packaging needs, the responsible disposal and recycling of these ubiquitous materials become equally paramount. Cardboard recycling involves a systematic process of collaborating with waste management companies to guarantee the efficient reuse and repurposing of old corrugated containers.

Preparation for recycling includes removing packing materials and flattening boxes for efficient processing. However, grease-soiled cardboard cannot be recycled due to contamination issues in the recycling process. Conversely, tape and labels can be left on cardboard boxes as they are typically removed during the recycling procedure.

Industrial environments often utilize cardboard balers to compact cardboard for more efficient storage and transportation to recycling facilities.

Conclusion

Corrugated cardboard is a versatile and widely used packaging material. The composition, flute characteristics, and grades of cardboard determine its strength and suitability for various applications.

Key corrugated box styles offer different functionalities, while adherence to recycling standards promotes sustainability.

Understanding the nuances of cardboard types and specifications is essential for selecting the appropriate packaging solution.