The Ultimate Guide to Rigid Boxes Everything You Need to Know

2025-08-08 07:28:49.jpg)

Rigid boxes are made from high-density paperboard and chipboard, ensuring they don't fold or collapse easily. These boxes are assembled during manufacturing with precise dimensions, adhesive application, and paper wrapping. Using multiple layers of pressed paperboard, they offer unmatched durability and protection, ideal for high-end packaging. Customization options include material choice, structural design elements like magnetic closures, and various finishing techniques. Their robust structure and visual appeal make them perfect for enhancing your brand's market presence and consumer experience. Continue exploring to uncover more about the types, customization, and benefits of rigid boxes.

Key Takeaways

- Rigid boxes are made from high-density paperboard, ensuring durability and premium appearance.

- They feature customizable thickness and multiple layers for optimal protection.

- Types include telescoping, shoulder, clamshell, and book-style boxes.

- Customization options include material choice, structural design, printing, and finishing touches.

- High-quality craftsmanship in rigid boxes enhances both functionality and visual appeal, boosting brand presence and sales.

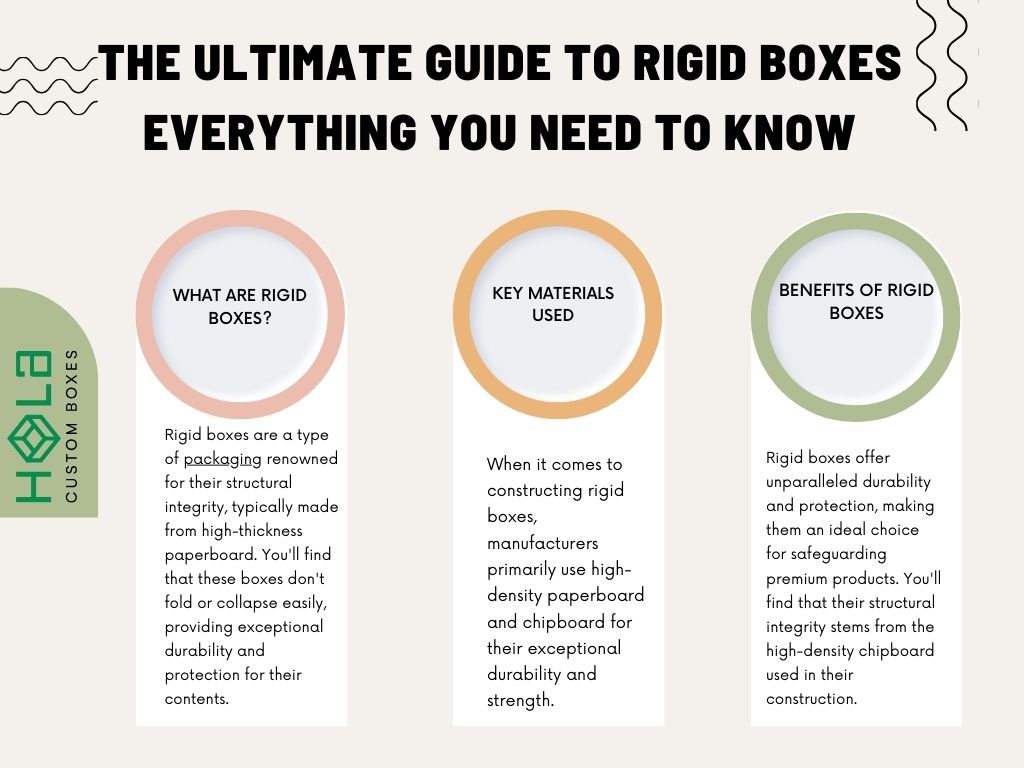

What Are Rigid Boxes?

Rigid boxes are a type of packaging renowned for their structural integrity, typically made from high-thickness paperboard. You'll find that these boxes don't fold or collapse easily, providing exceptional durability and protection for their contents.

Unlike folding cartons, rigid boxes are assembled during manufacturing and remain in their box shape. Their robust construction comes from the multiple layers of pressed paperboard, enhancing their strength and making them ideal for high-end product packaging. They often feature a seamless finish, offering a premium look and feel.

The rigidity ensures that the box maintains its shape, safeguarding delicate or valuable items. With their solid build, these boxes are perfect for luxury goods, electronics, and other premium products requiring superior protection.

Key Materials Used

When it comes to constructing rigid boxes, manufacturers primarily use high-density paperboard and chipboard for their exceptional durability and strength. High-density paperboard offers a smooth surface that's ideal for printing detailed designs, ensuring your branding looks sharp.

Chipboard, on the other hand, is known for its robustness and cost-effectiveness, making it a preferred choice for the internal structure.

You'll find that these materials provide the necessary rigidity, which is crucial for protecting valuable or delicate contents. Additionally, the thickness of these boards can be customized to meet specific requirements, offering flexibility in design.

Manufacturing Process

To achieve the desired durability and aesthetic appeal of these high-quality materials, the manufacturing process involves a series of meticulously coordinated steps that ensure each rigid box meets stringent standards.

First, you'll cut the chipboard to precise dimensions, forming the box's core structure.

Next, adhesive is applied, and the chipboard is assembled into the box shape.

Once the structure is complete, you'll wrap it with a printed or textured paper, ensuring seamless edges and corners for a polished look.

The final stage involves quality checks for alignment, adhesion, and finish.

Each step is critical to maintaining the box's rigidity and visual appeal, making the manufacturing process both an art and a science.

Types of Rigid Boxes

Rigid boxes come in a variety of styles, each tailored to suit specific packaging needs while enhancing product presentation. Telescoping boxes are among the most common, featuring a classic two-piece design with a separate lid and base—perfect for packaging premium goods. Shoulder boxes, on the other hand, incorporate an inner tray that separates the lid from the base, offering a more refined unboxing experience and improved structural integrity. Clamshell boxes stand out for their hinged lid design, providing both convenience and security, making them ideal for luxury electronics and upscale items.

Material and Functional Benefits

Typically constructed from high-density paperboard or chipboard, rigid boxes are known for their durability and premium feel. Styles like the book-style box, which opens like a hardcover book, are commonly used for collector’s items and gift sets, adding a sense of elegance and anticipation. Each type of rigid box serves not just as protection for the product but also as a tool to elevate brand perception and customer experience.

Customization Options

You have a plethora of customization options to ensure your rigid boxes align perfectly with your brand's aesthetic and functional needs.

Start with material choices: opt for high-quality paperboard or specialty materials like leather or fabric.

You can then select a structural design—magnetic closures, hinged lids, or slipcases offer varied functionality.

Printing techniques such as embossing, debossing, and foil stamping add tactile and visual appeal.

For added protection, consider custom inserts made from foam, cardboard, or molded pulp tailored to fit your product.

Don't overlook finishing touches like spot UV, lamination, or matte/glossy coatings.

Each element can be precisely tailored to create a cohesive, high-end presentation that reflects your brand's identity and meets practical requirements.

Benefits of Rigid Boxes

Rigid boxes offer unparalleled durability and protection, making them an ideal choice for safeguarding premium products. You'll find that their structural integrity stems from the high-density chipboard used in their construction. This material not only provides a robust framework but also ensures resistance to crushing and external pressures.

The rigid design minimizes the risk of deformation, maintaining the box's shape even under stress. Additionally, their multi-layered construction enhances shock absorption, reducing the potential for damage during transit.

The smooth exterior finish allows for high-quality printing and laminations, ensuring your branding remains intact and visually appealing. By choosing rigid boxes, you're investing in a packaging solution that combines strength, longevity, and aesthetic appeal, ensuring your products remain secure and presentable.

Common Uses

Given their durability and aesthetic appeal, these robust packaging solutions find extensive use in luxury goods, electronics, and high-end retail products. The structural integrity of rigid boxes ensures that delicate and valuable items are well-protected during transit and storage. Their premium look and feel elevate the customer experience, making them ideal for:

Jewelry and Watches: Securely housing precious metals and gems.

Smartphones and Gadgets: Providing shock resistance and a high-end unboxing experience.

Cosmetics and Perfumes: Enhancing the brand's luxurious image while safeguarding contents.

Fashion Accessories: Ensuring items like belts, scarves, and sunglasses remain pristine.

The material strength and precision engineering of rigid boxes make them a top choice for industries prioritizing both protection and presentation.

Eco-Friendly Options

Increasingly, manufacturers are turning to eco-friendly materials like recycled paperboard and biodegradable adhesives to produce rigid boxes that meet both environmental and consumer demands. You can find rigid boxes crafted from high-quality, post-consumer recycled content, which significantly reduces waste and conserves natural resources. The structural integrity remains uncompromised, ensuring durability and protection for your products.

Moreover, biodegradable adhesives offer a sustainable bonding solution without sacrificing performance. These adhesives break down naturally, reducing the environmental impact.

Cost Considerations

Considering the initial investment and long-term benefits, evaluating the cost of rigid boxes involves a detailed analysis of material expenses, production processes, and potential economies of scale. You'll need to consider several factors to make an informed decision:

Material Costs: High-quality materials like premium paperboard or specialty coatings can increase expenses but offer durability and aesthetic appeal.

Production Processes: Techniques such as die-cutting and lamination add precision and strength but also affect costs.

Volume Discounts: Ordering in bulk can reduce per-unit costs, making large orders more economical.

Customization: Unique designs, printing, and finishes enhance your brand but add to the overall cost.

Carefully analyzing these factors ensures you balance quality and budget effectively.

Choosing the Right Supplier

Selecting the right supplier for your rigid boxes demands a thorough evaluation of their production capabilities, material quality, and reliability.

First, assess their production capacity. Can they handle large orders without compromising quality?

Next, scrutinize the materials they use. High-grade paperboard and impeccable finishes ensure durability and aesthetic appeal.

Additionally, check their consistency in meeting deadlines; reliability is crucial in maintaining your supply chain.

Don't forget to request samples to gauge the precision of their craftsmanship.

Finally, consider their customization options. Can they tailor designs to fit your brand's needs?

A supplier that excels in these areas will ensure your rigid boxes are both functional and visually compelling, enhancing your product's market presence.

Conclusion

In conclusion, rigid boxes offer unmatched durability and premium presentation. With 60% of consumers saying packaging influences their purchase decisions, investing in high-quality materials and customization can significantly boost your brand's appeal.

From various materials like chipboard and paperboard to eco-friendly options, each aspect of rigid box manufacturing demands careful consideration. Partnering with a reliable supplier ensures you get the perfect mix of quality and cost-efficiency for your specific needs.