How to Measure a Box for Custom Packaging

2025-09-26 09:37:43

How to Measure a Box for Custom Packaging

When ordering custom packaging, one of the most common challenges businesses face is getting the measurements right. The size of your packaging impacts not only the look and feel of your product but also shipping costs, material usage, and customer experience.

Learning how to measure a box for custom packaging ensures that your product fits securely, looks professional, and reduces waste. Whether you need packaging for cosmetics, food, or retail products, accurate measurements are key to creating the perfect custom box.

At Hola Custom Boxes, we guide our clients through every step of the packaging design process, starting with accurate measurements to ensure the best fit and finish.

Why Accurate Box Measurements Matter

Before we dive into the process, it’s important to understand why correct measurements are critical:

Product Protection: A box that’s too small risks damaging your product, while one that’s too large increases shipping costs and looks unprofessional.

Cost Efficiency: Proper measurements ensure you aren’t overpaying for excess material or void fillers.

Branding Impact: Custom boxes designed to fit perfectly make your packaging look sleek and high-quality.

Shipping Compliance: Accurate sizing helps calculate shipping rates and prevents dimensional weight charges.

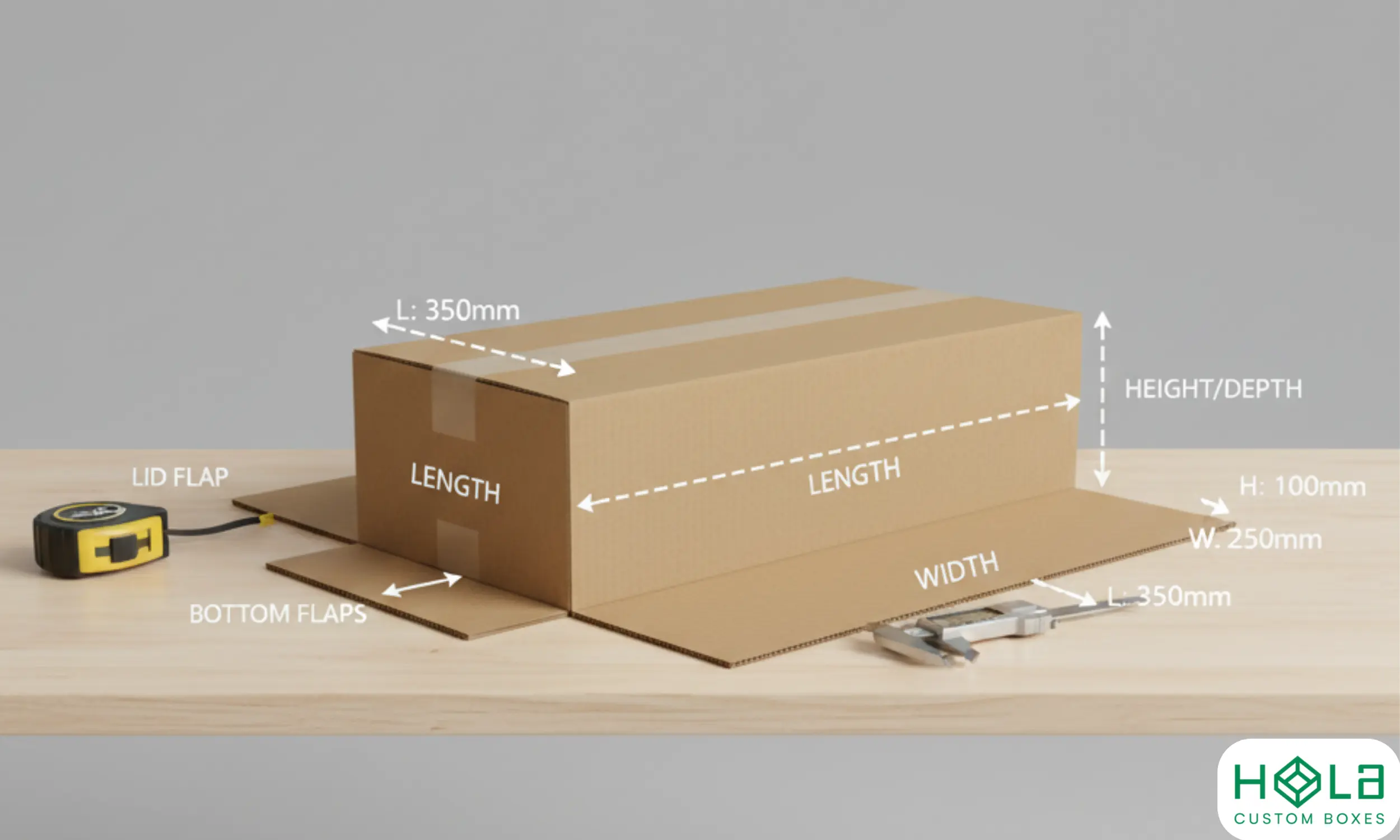

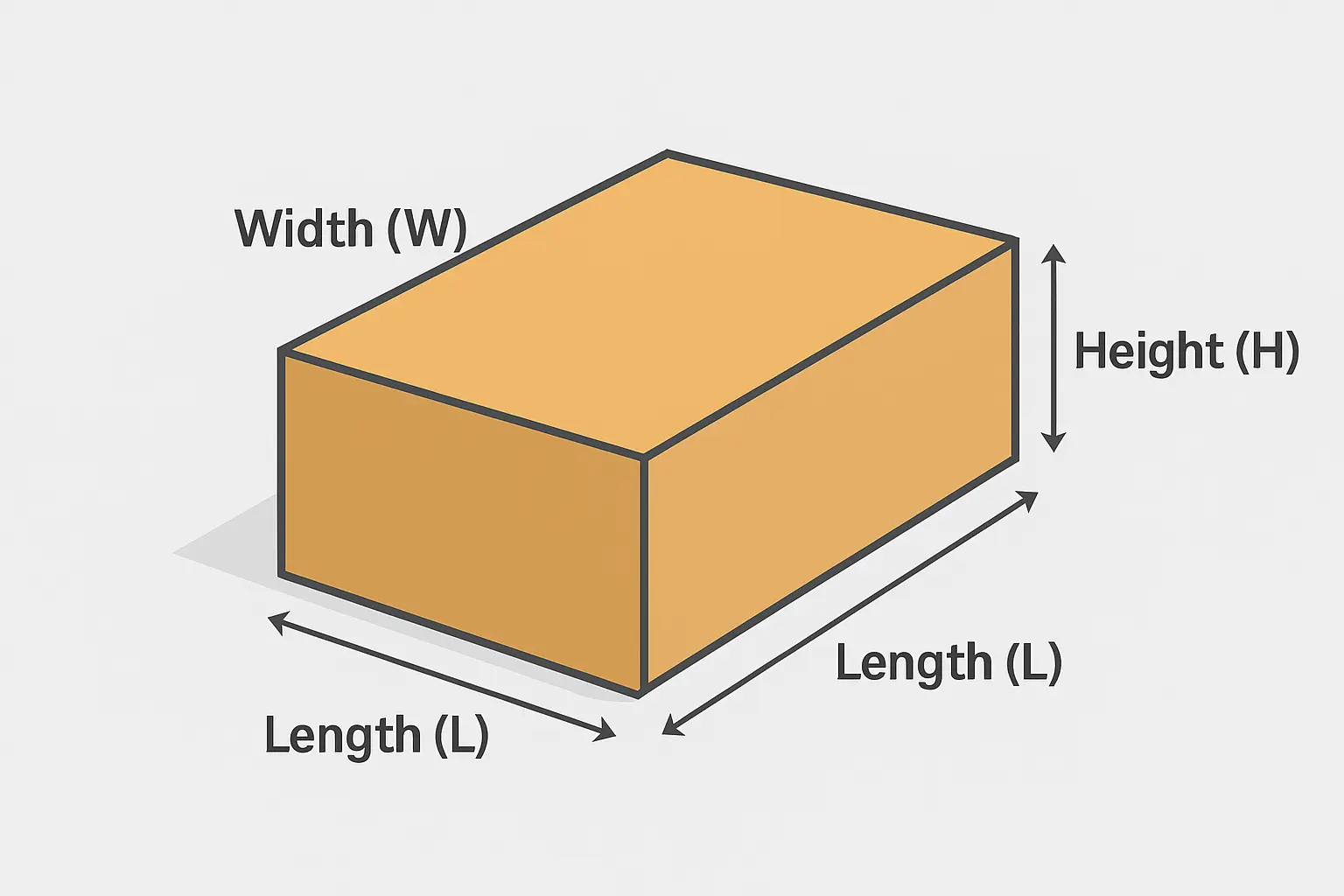

Step 1: Understand the Three Dimensions of a Box

When measuring for custom packaging, always note that dimensions are given in the order of length × width × depth (or height).

Length (L): The longest side of the box when looking at the opening.

Width (W): The shorter side of the opening.

Depth/Height (H): The distance from the opening to the base.

Example: A soap box may be 2.5" (L) × 1.5" (W) × 3" (H).

Step 2: Measure the Inside, Not the Outside

For packaging, interior dimensions matter most. Always measure the inside of the box since that’s where your product will sit.

Use a measuring tape or ruler for precision.

Round up slightly if your product has irregular edges or needs extra space.

Don’t forget to account for inserts, dividers, or cushioning if your design requires them.

Step 3: Consider the Product Shape and Orientation

Different products require different orientations inside the box. For example:

Cosmetics like lipstick or mascara often fit better vertically.

Food items such as custom noodle boxes or coffee packaging usually require horizontal layouts.

Retail products like apparel may need flat, wide boxes.

By measuring according to your product’s best orientation, you’ll ensure an optimal fit.

Step 4: Add Allowances for Safety and Presentation

When planning box measurements, leave room for:

Protective inserts (foam, cardboard dividers, or molded trays).

Wrapping material (tissue paper, eco-fillers, or bubble wrap).

Ease of opening so customers don’t struggle with tight packaging.

Step 5: Match Box Style to Measurements

Different box styles use dimensions differently. For example:

Reverse tuck end boxes: Measurements define the product cavity.

Rigid boxes: Often require extra allowance due to thicker walls.

Corrugated mailers: Measured flat, then folded into shape.

At Hola Custom Boxes, our experts help match your measurements to the right box style for cosmetics, food, or retail products.

Common Mistakes to Avoid

Measuring outside instead of inside: This leads to poor product fit.

Not accounting for inserts: Especially important for fragile items.

Ignoring product extras: Caps, lids, or tags may require extra space.

Mixing up width and depth: Always follow the L × W × H sequence.

Practical Examples

Custom Soap Boxes: For a bar of soap measuring 2.25" × 1.25" × 3", the box should be slightly larger (e.g., 2.5" × 1.5" × 3.25").

Custom Candle Packaging: A candle jar with a 3" diameter and 4" height needs a box at least 3.25" × 3.25" × 4.5".

Custom Coffee Boxes: A 12 oz coffee bag may require extra space at the top for sealing and resealing.

FAQs About Measuring Boxes for Custom Packaging

Q1: Should I measure in inches or centimeters?

Most packaging manufacturers prefer inches, but confirm with your supplier.

Q2: Do inserts affect box size?

Yes. Always include the thickness of inserts, dividers, or trays in your measurements.

Q3: What if my product has an irregular shape?

Measure the longest, widest, and tallest points to ensure a secure fit.

Q4: Can I send my product to the packaging supplier?

Yes. Many companies, including Hola Custom Boxes, offer product fitting services for accuracy.

Q5: What’s the most common mistake small businesses make?

Mixing up width and depth—always double-check your sequence: length × width × depth.

Conclusion

Accurate measurements are the foundation of custom packaging success. By measuring correctly, you save money, improve protection, and elevate your brand’s presentation.

At Hola Custom Boxes, we work with businesses of all sizes to create perfectly measured custom boxes for everything from cosmetics to food and retail.

Ready to get started? Contact us today and let us design packaging that fits your products—and your brand—perfectly.