How to Find the Best Custom Packaging USA Supplier

2026-01-01 12:29:56

How To Find The Best Custom Packaging USA Supplier

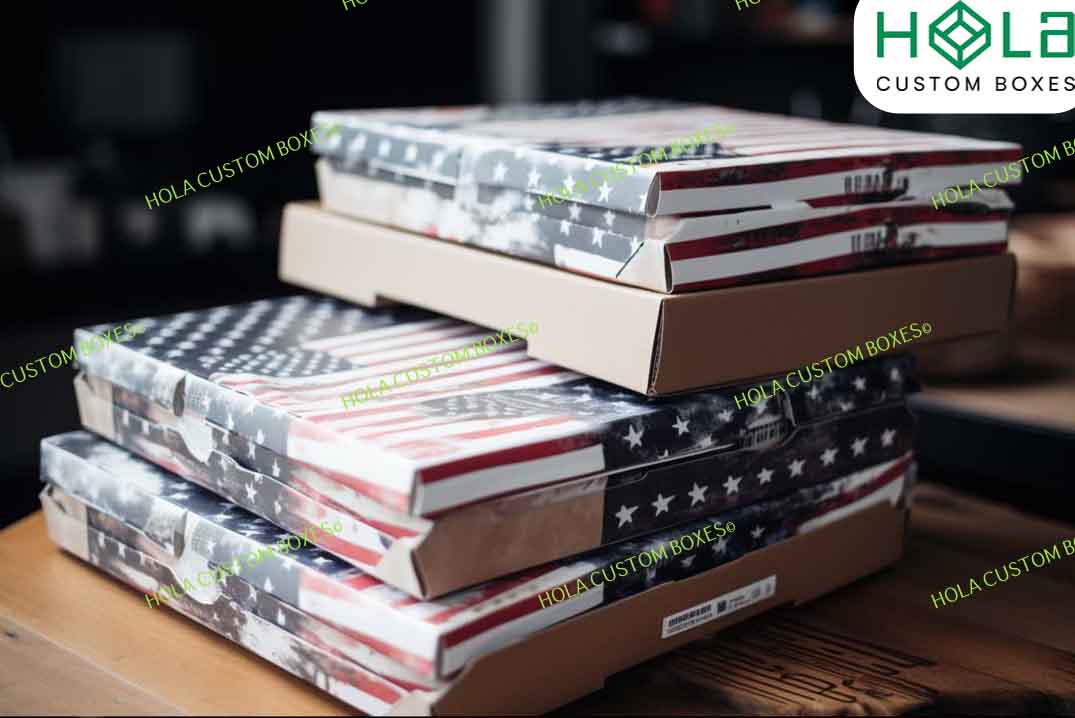

Custom packaging suppliers in the USA offer a range of services to businesses and individuals. From printing labels and boxes to designing custom shipping containers, these suppliers can help customers create the perfect product package. This article will explain how to find the best supplier for custom packaging needs in the United States.

The first step is thoroughly researching potential suppliers. Comparing companies that offer similar services and reading reviews from past clients is essential. Additionally, it is wise to contact multiple suppliers directly so they can answer questions about pricing, turnaround times, materials used, and any other inquiries one may have. Understanding each company's capabilities can help narrow down the choices even further. Finally, if possible, visit a showroom or facility to get an up-close look at the type of work the supplier does before deciding.

Compare trusted Custom Packaging Manufacturers for nationwide delivery.

Identify Your Custom Packaging Needs

Finding the best custom packaging USA supplier starts with determining your product size, weight, and fragility. This information is necessary to ensure that the chosen supplier can meet all of your needs for both safety and cost-effectiveness.

Additionally, consider your branding requirements for the packaging design and any marketing messages to better promote your product. Once these criteria are established, it is essential to identify a budget so you know which type of custom packaging provider is financially within reach.

With this data, you are ready to begin researching potential suppliers offering quality products at competitive prices.

Order premium Rigid Boxes at wholesale rates.

Research Potential Suppliers

When looking for the best custom packaging supplier in the USA, it is essential to conduct thorough research.

Online directories and search engines are great places to start searching for potential suppliers; they provide detailed information about packaging industry companies that offer services such as printing, lamination, labeling, and more.

Additionally, asking for recommendations from industry peers or trade associations can help narrow down the list of potential suppliers by providing insights into their quality of service and reliability.

Finally, visiting trade shows and exhibitions is another way to connect with professionals in the field while getting an up-close look at different products on display. This can be useful for making informed decisions when selecting a reliable custom packaging supplier in the USA that meets specific needs.

Evaluate Supplier Capabilities

When selecting a custom packaging supplier in the USA, it is essential to evaluate their manufacturing capabilities. When assessing a potential supplier's production abilities, volume and quality are two primary considerations. They must meet your current and future needs regarding volume and quality. Additionally, determine if they can provide customization options for your specific product design requirements.

The customer service offered by suppliers should also be considered when making an informed decision. The response time for inquiries and orders and their ability to answer any questions or address concerns quickly and efficiently must be regarded as.

Furthermore, assess how easy it is to contact them by phone or email on short notice, and whether they offer after-sales support services, such as returns processing and warranties.

Logistics play another key role in determining a suitable custom packaging provider in the US market. Check which delivery methods they offer; inquire about shipping times (domestic and international), the costs associated with each option, tracking availability, insurance coverage, etc., all factors that will ultimately affect your bottom line.

Get eco-conscious packaging with Eco-Friendly Boxes.

Finally, researching feedback from previous customers regarding their experience dealing with a particular company is always beneficial before committing to working with them long-term. Reviews posted online can provide insight into how reliable the supplier is in fulfilling clients' order fulfillment demands and into overall satisfaction with the products received over time.

Compare And Negotiate Quotes

When evaluating suppliers for custom packaging, it is essential to consider their capabilities and the quotes they provide. Comparing and negotiating these quotes can be time-consuming, but it pays off in the long run.

To begin comparing quotes from different suppliers, first make sure your requirements are clearly listed so each supplier knows the type of service or product you need. Once each proposal has been received, consider any additional costs associated with taxes, shipping, project management, etc., as well as potential discounts offered by certain suppliers. Lastly, analyze the terms of each quote — such as payment deadlines and delivery timescales — to determine which best meets your needs before making your decision.

It is also essential to factor in other considerations when deciding on a supplier, including assessing their customer service track record and level of technical expertise required for the job at hand. Any reputable vendor should be willing to answer questions about their services or products honestly and accurately before a contract is signed. Furthermore, if there are any concerns regarding quality control standards, this should be discussed during negotiations as early as possible to avoid delays further down the line.

By systematically comparing and negotiating quotes from various vendors, businesses can ensure they receive the best value for money while still meeting their individual goals. It's important to remember that price isn't always an indicator of quality - instead, focusing on factors such as reliability and trustworthiness will help find a suitable partner who provides excellent products and services without breaking the budget.

.jpg)

Test And Verify The Quality

The quality of custom packaging is paramount for protecting a product and creating an attractive design. It's no exaggeration to say that a brand's success or failure can hinge on this critical component. For businesses to ensure they provide the highest-quality craftsmanship, thorough testing and verification must be done with any chosen supplier.

Testing involves examining the physical aspects of the package, including durability, functionality, aesthetics, and overall appearance. Particular attention should be paid to printing accuracy, surface treatments, die-cutting precision, folding strength, and more. Additionally, samples should be obtained from suppliers to verify their ability to provide consistent results across large production runs.

It is also essential to confirm that all processes meet industry standards and regulations on safety and environmental concerns. For example, certain materials may require special certifications due to health risks associated with their use or disposal methods. Verifying these requirements upfront will help protect companies from costly fines if not appropriately addressed.

With so much at stake, it becomes clear why those seeking custom packaging solutions need reliable partners who consistently deliver high-quality products while meeting all applicable regulations—the assurance that only comes from rigorous testing and verification protocols throughout the process.

Monitor And Improve The Partnership

When finding the best custom packaging supplier, specific steps should be taken to ensure quality and effective partnerships. Testing and verifying sample quality is a significant first step. However, once an agreement has been made and orders have begun shipping, ongoing monitoring is necessary to ensure all agreement terms are met. This includes monitoring production times, assessing customer service levels, evaluating product safety standards, and maintaining supplier communication.

Monitoring should include regular reviews of performance metrics, such as project turnaround time, cost per unit, and total costs incurred against quotes provided. It also involves tracking customer satisfaction through surveys or other feedback mechanisms, including customer complaints about product issues or a lack thereof. These evaluations can help identify areas where improvements may need to be made on both sides—the supplier's side for production processes and the end-users side for expectations around their desired product outcomes.

Improving existing relationships requires investment from both parties; suppliers must invest in improving their production practices, while buyers should commit resources to learning more about their partners' operations so they can offer meaningful advice when needed. Additionally, rewarding good work by recommending them to others or providing incentives will further encourage better partnerships between buyer and supplier.

Finally, mutual understanding must exist between the two entities: what works for one company might not work for another due to differing needs and preferences across markets. Understanding each partner's unique requirements is crucial to forming successful collaborations that yield mutually beneficial outcomes in the long run.

In summary, testing sample materials is fundamental. Still, ongoing monitoring of performance metrics helps maintain strong relationships between buyers and suppliers, ultimately leading to improved collaboration and optimal products tailored to their intended market audience.

Choose quality, choose Hola Custom Boxes — your U.S. packaging partner.

Conclusion

Custom packaging is the key to creating a successful product. It can make or break your reputation with customers and ensure that items arrive safely and securely. Finding a reliable custom packaging supplier in the USA who can meet your needs requires careful research, detailed evaluation, and quote comparison. When selecting the right partner for your business, knowledge is power as you negotiate terms, quality assurance protocols, timelines, shipping options, and more.

The best way to succeed with custom packaging is by investing in an ongoing relationship with a trusted vendor. A good provider will be responsive and stay up to date on industry trends, so they can provide feedback on how best to package products, with efficiency and cost savings in mind. With the right supplier, you'll have peace of mind and confidence that your goods are packaged correctly every single time – no matter their size or shape.