How Much Does Package Design Cost?

2025-09-13 11:39:17

How Much Does Package Design Cost?

Expect packaging design to cost $300–$800 for simple layouts, $800–$1,500 for intermediate work, $1,500–$3,000 for premium engagements, and $3,000+ for bespoke programs.

Your final price hinges on design complexity, customization (shapes, substrates, coatings), scope, vendor location (20–40% variance), and order quantity. Per-unit costs drop with higher volumes; standardized CMYK and finishes help.

DIY can be ~$100, freelancers $1k–$10k, agencies $10k–$20k. Budget a 10–20% contingency and factor revisions, structural work, and packaging layers—there’s more to optimize.

Main Points

- Package design costs range from $100 DIY to $20,000+ with agencies, depending on scope and expertise.

- Typical projects: $300–$800 simple, $800–$1,500 intermediate, $1,500–$3,000 premium, $3,000+ bespoke luxury.

- Costs rise with design complexity, customization, structural work, and revision rounds.

- Production choices and quantities affect per-unit costs; bulk orders can save 15–40%.

- Request transparent pricing, define deliverables, and keep a 10–20% contingency for changes.

What Factors Influence Packaging Pricing

Whether you’re budgeting for a refresh or a full rebrand, packaging pricing hinges on a few quantifiable drivers.

These include design complexity (more intricate dielines, illustrations, and finishes), customization (non-standard shapes, sizes, substrates, and coatings), and order quantity (larger runs release economies of scale and lower per-unit costs).

Other factors are vendor location (firms in lower-cost regions often quote 20–40% less than North America/Western Europe) and process scope (extended collaboration, stakeholder reviews, and multiple revision rounds expand billable time).

You’ll control packaging design costs by prioritizing the key factors that impact scope: customization options, quantity ordered, and geographic location.

Plan for extensive collaboration and revisions during the design process to align with client expectations and branding guidelines without scope creep.

For quick turnarounds that may affect pricing, Hola Custom Boxes offers rush order options and responsive support via online quote requests and phone or email.

Cost Ranges by Design Complexity and Customization

Although every brief is different, packaging design costs track closely to complexity and customization.

Entry-level work costs about $300–$800 for simple layouts with limited revisions. Intermediate packages land at $800–$1,500 with custom color schemes and moderate revisions.

Premium engagements for established brands typically price at $1,500–$3,000 with deeper typography and brand research.

Bespoke luxury programs start at $3,000+, reflecting extensive immersion, unlimited revisions, and detailed production specifications.

For most SKUs, retail packaging boxes keep dielines standardized and costs predictable.”

You’ll match spend to design complexity and the customization you need. Basic packaging design focuses on core design elements. Intermediate packaging designs refine a brand’s identity.

Premium packaging designs expand research-driven systems. Bespoke luxury packaging delivers tailored, specification-heavy outcomes. The cost of packaging design scales accordingly.

For urgent timelines, many providers offer rush order options that can expedite design and production at an additional cost.

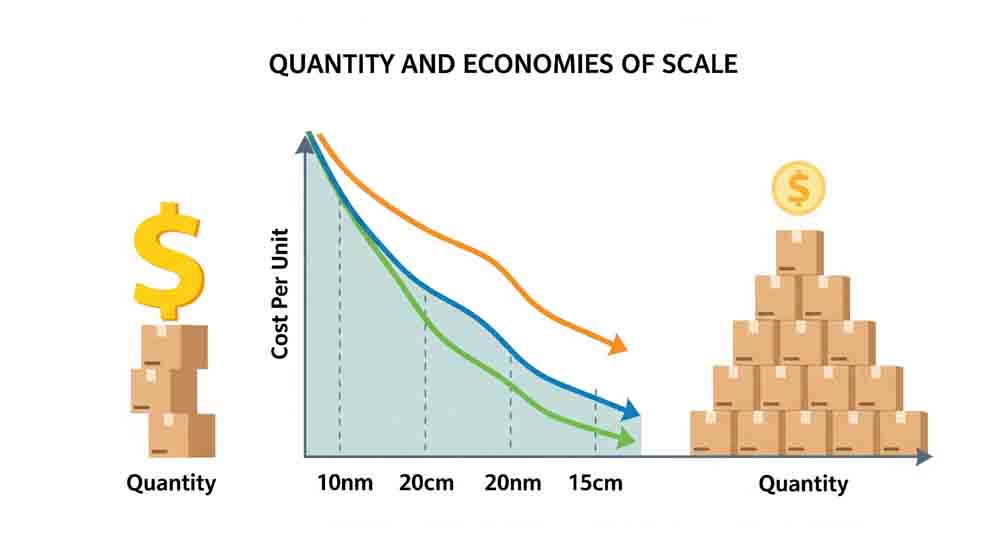

Quantity, Economies of Scale, and Per-Unit Costs

Every unit gets cheaper as volume rises because fixed setup, plate, and tooling costs spread across more pieces, driving measurable economies of scale.

You’ll see per-unit cost drop as quantity increases, especially when production costs include multi-up die cuts, longer press runs, and consolidated freight.

If you’ve got high-volume needs, bulk ordering typically yields 15–40% savings versus small batches.

Simplify packaging design to amplify scale effects.

Align quantities with sales forecasts and market demand to avoid carrying costs or stockouts.

Adjust pricing strategies as competitors shift.

Premium work (foil, rigid, magnets) lives in custom rigid gift packaging boxes

Model cost considerations by breakpoints: 1k, 5k, 10k, 50k units, then lock commitments accordingly.

For even greater efficiency at scale, leverage CMYK printing and standardized finishes to streamline runs and reduce changeover time.

Comparing Design Approaches: DIY, Freelancers, and Agencies

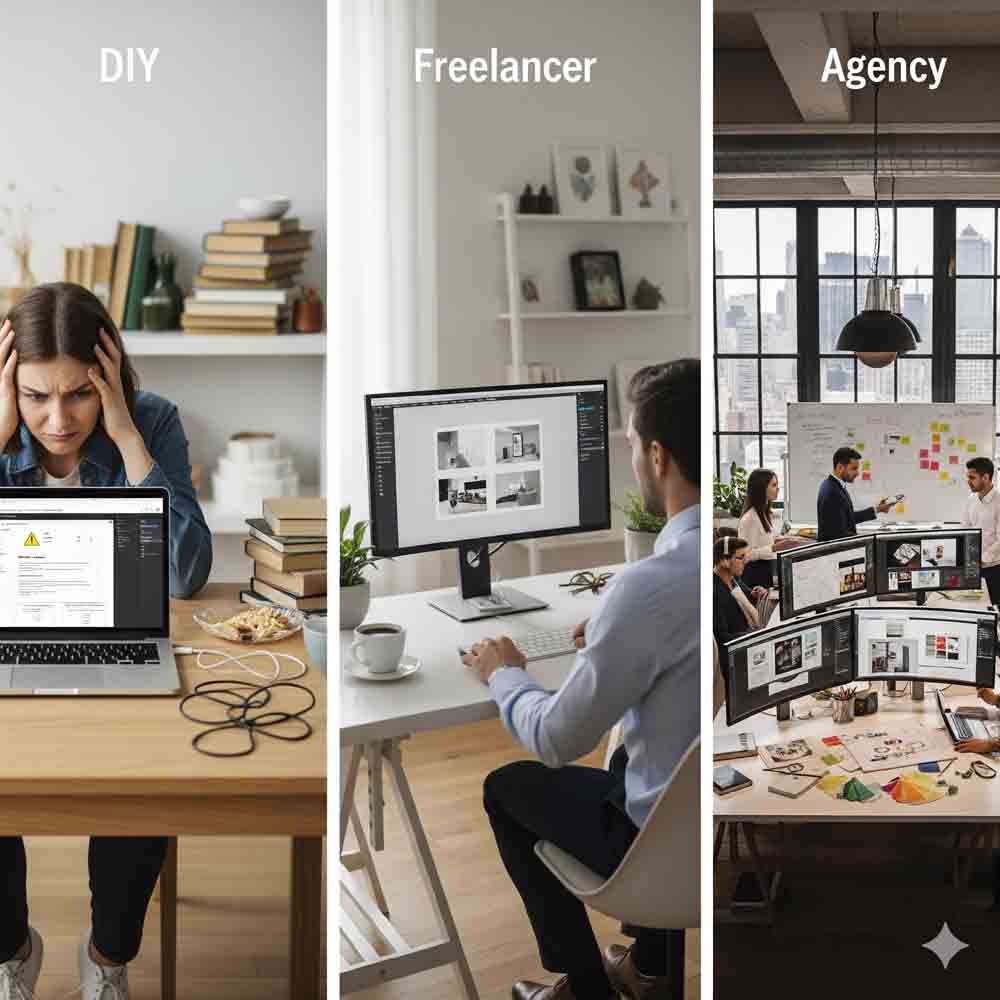

If you’re weighing DIY, freelancers, and agencies for packaging design, anchor the choice to budget, deliverables, and risk tolerance.

DIY packaging design costs ~$100 or less—good for small businesses—yet often sacrifices professional quality and consistency.

Freelance designers span ~$1,000–$10,000 based on scope and experience, balancing project costs with improved packaging quality and flexible deliverables.

Design agencies average ~$10,000–$20,000, reflecting deeper expertise, integrated teams, and tighter project management.

- A $99 template vs. a shelf-ready SKU

- Solo creative vs. multi-disciplinary squad

- Email threads vs. structured sprints

- “Good enough” mockup vs. validated market fit

Make budgeting decisions by matching design approach to risk and required deliverables.

The Packaging Design Process and Deliverables

While scopes vary by brand and budget, a typical packaging design workflow runs from concept development to production-ready art, with costs and timelines tied to deliverables at each stage.

You’ll start with initial design concepts, then move into design execution and revisions. Basic design packages limit concepts and 1–2 revision rounds; premium tiers add deeper consumer research, structural design, and copywriting, increasing overall cost but lowering production risk.

Final production deliverables should include high-resolution files, production-ready art, dielines, material, color, and dimension specs, plus optional 3D mockups.

Validate print feasibility early to avoid rework and compress lead times.

Eco budgets often choose custom printed kraft packaging boxes

Layers of Packaging and Their Cost Implications

Because packaging costs accrue at each layer, map spend across primary, secondary, and tertiary components before you brief design.

Primary packaging drives unit cost due to product contact and regulatory specs; secondary packaging balances shelf impact with material efficiency; tertiary packaging trades durability for bulk savings.

Quantify cost implications by SKU, material, and run size; larger orders access economies of scale.

Prioritize branding consistency to protect perceived value without overengineering. Limit customization to revenue-critical touchpoints.

- Glossy primary bottle with tamper band

- Litho-laminated secondary carton with spot UV

- Kraft RSC shipper with two-color print

- Palletized tertiary wrap with corner boards

Budgeting Tips and Pricing Transparency Strategies

You’ve mapped costs across primary, secondary, and tertiary layers; now lock that insight into a realistic design budget. Anchor ranges: packaging design can run from $100 DIY to $20,000+ agency.

Demand pricing transparency—hourly vs project vs packaged—before you approve scope. List additional expenses: revisions, structural work, dielines, file prep. Fund market research and consumer testing to drive effective packaging design.

Protect timelines by adding a 10–20% contingency. Track design costs weekly and freeze change requests.

Want a real quote? Share specs and explore retail packaging or rigid gift options.

| Line Item | Typical Range | Notes |

|---|---|---|

| Strategy | $500–$5,000 | Scope, personas |

| Design | $1,000–$15,000 | Iterations |

| Research/Testing | $1,000–$8,000 | Validation |

| Production Prep | $300–$3,000 | Print-ready files |

Frequently Asked Questions

How Much Should I Charge for Packaging Design?

Charge based on project scope and design value: set hourly rates, then quote flat fees aligned to client budgeting and client expectations.

Use pricing strategies informed by competitive analysis and market research. For basic packs, price lower; add premiums for package materials guidance, structural needs, and design revisions.

Offer tiers with capped rounds. Provide addons for copywriting and testing.

Track time, complexity, and revision count to validate margins and prevent scope creep.

How Much to Charge for Packaging Illustration?

Charge $300–$3,000 for packaging illustration, tiered by design complexity and client expectations.

Anchor illustration pricing with market research, current packaging trends, and your freelancer rates versus agencies. Quote basics at $300–$800; mid-tier $800–$1,500; premium $1,500–$3,000+.

Include artwork licensing, color psychology, and branding strategies. Specify rounds of design revisions and add-ons.

Provide a detailed scope, timeline, and usage terms to control costs and justify value with measurable outcomes.

How Much to Charge for a Design Fee?

Charge by aligning project scope assessment with client budget considerations.

Use design pricing strategies: compare industry standards, apply value based pricing, and set clear design fee structures.

For freelance design rates, anchor $300–$3,000+ per package, scaling with complexity and revisions. Let design experience influence premiums.

Cite market research impact as an add-on. Offer tiered options, track hours, and cap revisions.

Use negotiation techniques: present anchors, justify deliverables, and show ROI-driven alternatives.

block (Recommended Products)