Eco-Friendly Subscription Packaging: Materials, Costs, and How to Switch

2025-11-28 10:34:07

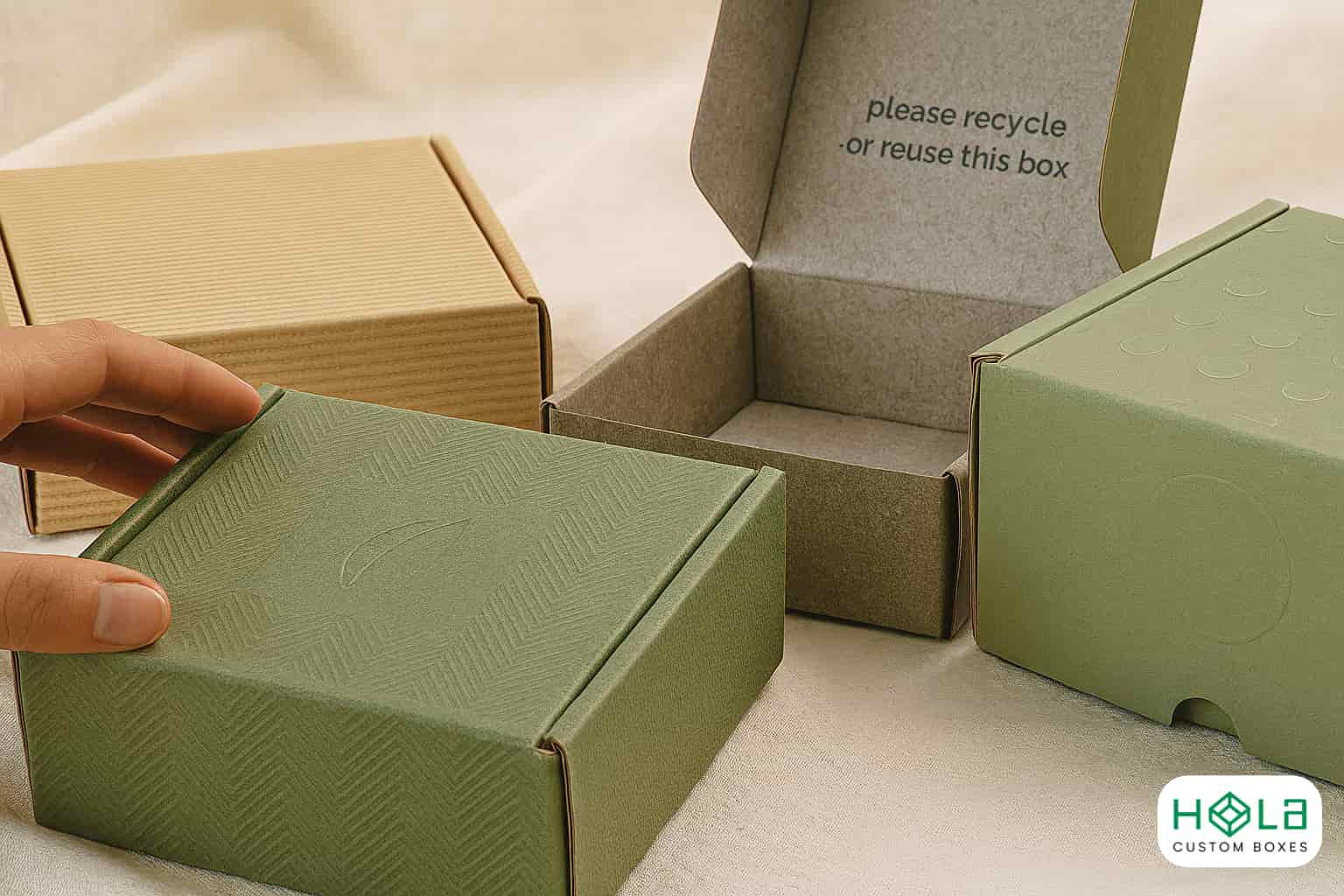

Eco-Friendly Subscription Packaging: Materials, Costs, and How to Switch

If you run a subscription brand, you can cut costs and emissions by switching to FSC-certified kraft corrugate, recycled poly mailers, and right-sized inserts—often reducing DIM weight 8–15% and damage rates 10–25%. Start with a cost-per-order model, audit suppliers for genuine certifications (FSC, SFI, Blue Angel), and plan a 4–8-week pilot by SKU. The upside is clear—but the pitfalls, trade-offs, and exact steps to execute are where it gets interesting.

Main Points

- Choose certified materials: FSC kraft boxes, recycled poly mailers, molded pulp inserts, recyclable thermal liners, and water-activated tape for strength and recyclability.

- Model total landed cost: include materials, freight (DIM savings 10–25%), and damage; molded fiber can cut breakage from ~3% to under 1%.

- Pilot 6–8 weeks on high-volume SKUs with randomized tests; track margin, damage credits, carrier surcharges, and pass/fail thresholds.

- Right-size packaging: target void ratios under 15%, standardize box footprints, and use on-demand sizing to reduce waste and shipping costs.

- Verify suppliers and claims: request FSC/PEFC, SCS Recycled Content, BPI/TÜV certificates; audit annually and ensure ISO 9001 and SPC quality controls.

Why Sustainable Packaging Matters for Subscription Brands

Although packaging is often treated as a cost center, it directly drives subscription KPIs: 71% of consumers say sustainable packaging influences purchase decisions, 59% will switch brands for greener options, and damaged deliveries can spike churn by 10–15%. Eco-friendly boxes made from recycled cardboard are lightweight and durable, supporting reusability and lowering energy use in production. For you, that translates to lower CAC, higher LTV, and better retention. Clear eco-claims on the unboxing insert can boost referral intent; track with unique QR codes and offer take-back or recycling instructions to reduce disposal friction.

Packaging isn’t just cost—it drives subscriptions: sustainability sways buys; damage fuels churn by 10–15%.

Right-size parcels to cut DIM weight and last-mile emissions; benchmark savings per shipment. Instrument returns with damage codes to pinpoint failure modes, then A/B-test protective features against breakage rates and cost per order.

Tie packaging choices to NPS, first-to-second-box conversion, and recurring margin.

Use reusable, recyclable, eco-friendly packaging materials (like Kraft or E-flute) with CMYK or Pantone printing to reduce waste while maintaining brand impact.

Key Eco-Friendly Materials and When to Use Each

Because material choices cascade into costs, emissions, and damage rates, you should match substrates to use cases and verify with metrics.

Use FSC-certified kraft corrugate (32–44 ECT) for mixed assortments; it balances compression strength and 40–60% recycled content. For apparel or low-risk SKUs, ship in recycled poly mailers (≥50% PCR); they cut volumetric weight and reduce breakage from moisture. You can also specify finishes like gloss, matte, or uncoated to align protection with brand presentation, leveraging eco-friendly options such as E-flute and recycled kraft stocks.

Choose molded pulp or paper foam for fragile items; ISTA 3A tests show >30% drop protection vs. crinkle fill.

For perishables, line boxes with recyclable thermal liners (paper-based or mycelium) and curbside-recyclable gel packs; validate with 48-hour lane simulations.

Seal with water-activated tape; it improves fiber tear and reduces pilferage. Print with soy/aqueous inks to maintain recyclability.

Publish material specs, PCR %, and recyclability icons on pack to drive disposal accuracy.

Additionally, consider custom kraft boxes made from recycled pine-wood pulp with CMYK/Pantone printing and special finishes to align eco-friendly branding with durable, protective packaging needs.

Cost Comparison: Sustainable vs. Traditional Options

Start by modeling total landed cost, not just unit price, because sustainable packaging often shifts expense across materials, freight, and damage. Consider how eco-friendly materials and FSC-certified options can improve brand perception while meeting sustainability goals.

Build a worksheet with five columns: material cost, weight-based freight, cube-based freight, packing labor, and damage/returns. Compare current corrugate/poly to recycled board, molded fiber, and paper mailers.

Use benchmarks: right-sizing reduces DIM weight 10–25%; switching from 200# to 32 ECT with paper void fill can cut weight 8–15%.

For apparel, paper mailers often save $0.12–$0.28 per parcel in freight despite a higher unit price. For fragile SKUs, molded fiber inserts reduce breakage from ~3% to <1%, offsetting an additional $0.20–$0.40 in materials.

Run A/B pilots for four weeks: 500–1,000 orders per variant. Track per-order margin, carrier surcharges, pick speed, and damage credits.

Select by lane and SKU mix.

If you need custom sizes, eco materials, or fast proofs, consider suppliers that offer sustainable packaging options with digital 2D/3D proofing and low minimums to streamline testing and rollout.

Certifications That Actually Signal Environmental Impact

While logos crowd packaging, only a few certifications verify measurable impact and supply-chain integrity.

Prioritize third-party standards with traceable chains of custody and quantifiable criteria. For fiber, FSC (Mix or 100%) and PEFC guarantee legal sourcing; pair with FSC Chain of Custody for audit-ready documentation.

For recycled content, look for SCS Recycled Content or UL ECOLOGO with percentage claims; target ≥50% PCW for mailers and inserts.

For compostables, demand BPI or TÜV OK Compost Industrial; for home compost, require TÜV OK Compost Home.

For plastics, use How2Recycle for clear consumer disposal and APR Design Guide compliance to protect MRF yield.

Operationalize: ask suppliers for current certificates, scope details, and lot-level COC numbers; integrate certification fields into your POs; audit annually; publish SKUs’ certification matrix to reduce greenwashing risk.

Additionally, when evaluating formats like fold-and-assemble boxes, consider the material and design options—such as cardboard, corrugated layers, and water-resistant treatments—to align certifications with durability and protection needs.

Right-Sizing and Design Tactics to Reduce Waste and Fees

Even small dimensional trims cut material use, freight spend, and damage rates when you engineer packaging to the product’s actual cube and fragility. Leverage eco-friendly materials such as kraft or E-flute to balance protection with sustainability and keep weights down.

Audit order history to map SKU size variance; target your top 20% by volume. Model carrier DIM thresholds (e.g., 0.5) often shift parcels to lower zones or tiers. Aim for void ratios under 15%; every 10% reduction in voids cuts dunnage by up to 30%.

Audit SKU size variance; target top-volume items. Model DIM thresholds. Keep void under 15% to slash dunnage.

Use score-cut mailers, 1-2-3 auto-lock bottoms, and variable-height RSCs to eliminate air. Replace EPS with molded pulp or corrugated inserts designed via FEA to maintain 30–60 G drop protection. Consider leveraging eco-friendly options available in custom food boxes to reduce environmental impact while maintaining food-safe performance.

Standardize three to five box footprints, then deploy on-demand right-sizing for outliers. Print pack-out diagrams. Confirm pallet patterns; 5% better cube can cut LTL accessorials.

Supplier Sourcing and Vetting Checklist

Optimizing box geometry only works if your suppliers can consistently hit specs, document impacts, and scale.

Start by shortlisting vendors with verifiable certifications: FSC/PEFC for fiber, SFI chain-of-custody, and third-party LCA or EPDs for materials.

Require recycled content proofs (e.g., 80% PCW target) and confirm ASTM D6400/EN 13432 compliance if compostable.

Demand test data: ECT/BCT ratings, Cobb values, ink VOCs, and transit drop/ISTA 3A results.

Audit capacity and lead times: weekly throughput, surge buffers, and on-time-in-full (OTIF) >95%.

Validate pricing transparency: line-item material, ink, and freight; fuel and resin indexes; MOQs; scrap factors.

Inspect QA systems: ISO 9001, SPC charts, COA per lot.

Assess sustainability KPIs: energy mix, water intensity, defect rate, and take-back programs.

Pilot with A/B shipments before awarding 12-month contracts.

Leverage a supplier’s dedicated support structure to speed issue resolution and rush needs, confirming availability via Customer Support contact options and documented turnaround commitments.

Operational Changes That Minimize Disruption

Because packaging shifts can ripple through planning, start with a controlled rollout: convert 10–20% of SKUs with the highest ship volume and damage rates, then gate the next tranche on three-week stability metrics (OTIF ≥97%, damage <0.5%, pick speed ±2%).

Map where materials touch systems: update item masters (dimensions, weight, cube), cartonization rules, dunnage BOMs, and carrier service maps.

Re-slot fast movers to reduce travel and guarantee new box sizes align with pick faces and put-wall cells. Train associates with one-point lessons and scan prompts; enforce scan-to-pack to prevent mis-boxing.

Adjust labor standards by time study, not guesswork. Align carriers early on DIM factors and thresholds. Buffer inventory for both old and new packs to protect continuity while you burn down legacy stock.

Pilot Programs: Test, Measure, and Iterate

While you’ve stabilized core operations, launch a 6–8-week pilot across 10–20 high-volume subscription SKUs to validate eco-friendly packs under real-world constraints.

Define hypotheses, sample sizes, and pass/fail thresholds before day one. Randomize assignments to control for seasonality, and track costs end-to-end: materials, labor time, DIM weight, surcharges, and returns.

Predefine hypotheses, samples, and thresholds; randomize assignments; track end-to-end costs including DIM, surcharges, and returns.

- Instrument data: scan events for pick/pack time, package ID, carrier service, and delivered status.

- Monitor quality: damage rate ≤1%, leak/break thresholds by category, and ASN-to-receipt variances.

- Measure logistics impact: average cubic reduction, DIM tier shifts, and on-time delivery deltas versus control.

- Analyze unit economics: COGS deltas, per-order freight, and handling minutes; target payback <90 days.

- Iterate weekly: adjust dunnage density, box sizes, closures, and auto-bagger settings based on findings.

End with a go/no-go and a scaled rollout plan.

Communicating Sustainability to Subscribers

Use channel-specific CTAs:

- Unboxing card: QR to a 30-second LCA explainer and recycling how-to.

- Subscription portal: toggle shows legacy vs. new footprint per year.

- Post-purchase SMS: localized disposal instructions by ZIP.

Back claims with recognized standards (ISO 14067 LCA, How2Recycle labels) and audits.

Track uplift: email CTR, QR scans, reduced WISMO tickets, and NPS by cohort.

Incentivize correct disposal with loyalty points.

Scaling the Switch Across SKUs and Fulfillment Channels

You’ve validated messaging and measurement; now operationalize the packaging change at scale across every SKU and node.

Start with a bill of materials (BOM) audit by SKU, mapping dimensions, fragility, and thermal needs to right-size recyclable or compostable options.

Standardize packaging families (S, M, L) with <=10% void targets and confirm ISTA 3A/6-Amazon pass rates.

Pilot in two DCs, then roll network-wide once defect rate is <0.5% and pick/pack time stays flat.

- Build a SKU-to-pack matrix with cartonization rules in WMS and 3PL SOPs

- Lock supplier SLAs: lead time, MOQ, recycled content %, unit cost, CO2e per unit

- Train pickers with visual guides; measure UPH impact weekly

- Set cartonization APIs in OMS for DTC, marketplace, retail

- Track KPIs: damage rate, DIM weight, spend/SKU, CO2e/order, NPS

Frequently Asked Questions

How Do Eco-Friendly Packages Perform in Extreme Weather or Long-Distance Shipping?

They perform reliably when you match materials to conditions. Specify water-resistant coatings, reinforced seams, and certified crush strengths. Use 32–44 ECT corrugate, compostable liners, desiccants, and curbside-recyclable tapes. Validate with ISTA 3A/6A tests and track lane-level damage KPIs.

What Insurance Implications Arise When Switching to Sustainable Packaging?

You’ll face recalculated cargo rates, revised liability limits, and stricter proof-of-pack durability. Quantify drop/temperature performance, update ISTA certifications, notify carriers, and renegotiate terms. Add product-specific riders, adjust declared values, and validate claims data to prevent denied payouts and premium surcharges.

How Do Packaging Changes Affect Returns Processing and Refurbishment?

Packaging changes alter return rates, inspection time, and salvage yield. You’ll need barcode-rich RMA labels, drop-test data by SKU, and modular inserts. Track damage codes, refurb lead time, and COS. Pilot A/B packaging, then update SOPs and carrier handling instructions.

Can Sustainable Packaging Reduce Porch Theft or Improve Delivery Acceptance Rates?

Yes—subtle, sustainable packaging can reduce porch theft and improve acceptance. You deploy nondescript, right-sized mailers, curb branding, add QR delivery notes, request signature selectively, and use recycled void fill. Pilot A/B tests; track theft incident rate, acceptance scans, last-mile exceptions.

How Do Accessibility Needs Influence Eco-Friendly Packaging Design Choices?

Accessibility needs drive eco-friendly packaging by requiring easy-open tear strips, large-print labels, tactile markers, and curbside-recyclable mono-materials. You audit user segments, test FMECA for dexterity/vision, track open-rate defects, and swap plastic seals for paper tapes to meet ADA and ISO 17480 benchmarks.

Final Thoughts

You’re ready to cut footprint and costs by switching to eco-friendly subscription packaging. Prioritize FSC-certified corrugate, recycled poly mailers, and right-sized designs to lower DIM weight and damage rates by 10–25%. Audit suppliers for credible certifications, model total landed cost (materials + freight + breakage), and run 4–8 week pilots with A/B SKUs. Track cost per order, CO2e per shipment, and CSAT. Share results with subscribers and scale SKUs and 3PLs systematically to lock in savings.