Exploring Eco-Friendly Custom Ammo Box Printing Options for Your Brand

2025-10-08 04:13:02

Exploring Eco-Friendly Custom Ammo Box Printing Options for Your Brand

As environmental awareness continues to grow, even the ammunition industry is embracing sustainable practices. Brands that once focused solely on performance and protection are now turning their attention to eco-friendly packaging solutions that align with modern consumer values.

If you’re an ammunition manufacturer, reloader, or retail brand, the good news is that you don’t need to compromise durability or branding when going green. With the right design partner — like Hola Custom Boxes in Dallas, USA — you can produce custom ammo boxes that are both rugged and responsible.

Let’s explore how eco-friendly ammo box printing options can help you build a more sustainable, marketable, and future-ready brand.

Why Sustainable Packaging Matters in the Ammunition Industry

In the past, ammunition packaging was largely functional — meant to protect cartridges and meet compliance standards. But the packaging landscape has evolved.

Today’s consumers and retailers look beyond protection; they value ethics, sustainability, and eco-consciousness. That means your packaging choices now play a crucial role in your brand’s public image.

Key reasons ammo brands are going green:

Growing environmental regulations across the U.S. and Europe.

Military and law enforcement contracts now prefer recyclable materials.

Consumer demand for sustainable products and brands.

Social media visibility — eco-friendly branding resonates with a wider audience.

Sustainable packaging doesn’t just help the planet; it helps your brand stand out in a crowded industry.

What Makes Ammo Packaging Eco-Friendly?

Before diving into printing methods, it’s important to understand what defines eco-friendly packaging.

At Hola Custom Boxes, we follow three core sustainability principles for all custom ammo box printing:

Use of renewable or recyclable materials (like kraft and paperboard).

Eco-conscious printing processes that reduce chemical waste.

Minimal plastic use through smart design and coatings.

Each step — from design to delivery — is crafted to reduce your carbon footprint while maintaining the durability your ammunition requires.

Sustainable Material Options for Custom Ammo Boxes

Choosing the right substrate is the foundation of eco-friendly packaging.

Here are some top-performing materials we recommend:

| Material Type | Eco Advantage | Best For |

|---|---|---|

| Kraft Paperboard (Recycled) | 100% recyclable, natural look | Small bullet boxes, retail packs |

| Corrugated Cardboard | Lightweight yet strong | Shipping and bulk ammo cartons |

| FSC-Certified Paper | Ethically sourced wood fiber | Branded retail packaging |

| Uncoated Natural Paper | Plastic-free finish | Rustic or military-inspired aesthetics |

Each option can be customized with inserts, partitions, or sleeves for calibers like .22LR, 9mm, .45 ACP, or 12-gauge shells — without compromising strength or compliance.

Eco-Friendly Printing Options for Custom Ammo Boxes

Sustainability in packaging extends far beyond material — your printing choices matter just as much. Let’s explore the top environmentally friendly printing techniques available for custom ammo box branding.

1. Soy-Based and Vegetable Inks

Traditional petroleum-based inks release volatile organic compounds (VOCs) that harm the environment.

Soy-based inks are derived from natural oils, producing vibrant color without toxic emissions. They’re biodegradable, safe for recycling, and ideal for detailed logo or typography printing.

Benefits:

Excellent print clarity and color richness.

Low VOC emissions.

Works perfectly on kraft and matte surfaces.

2. Water-Based Inks

For brands aiming for zero toxicity, water-based inks are another clean alternative. They use water as the primary solvent, reducing pollution during production and recycling.

They’re particularly effective for digital or offset printing on eco-friendly materials like corrugated kraft.

Ideal for:

Short-run printing (custom calibers or brand variants).

Ammo brands that emphasize natural aesthetics.

3. UV Printing with LED Curing

A modern, energy-efficient method, UV LED printing uses light curing instead of heat or solvents. This minimizes energy consumption while ensuring crisp detail.

Key advantages:

Fast curing with minimal waste.

Durable and fade-resistant inks.

Perfect for moisture-resistant ammo box finishes.

4. Minimalist One-Color or Spot Design

Less ink = less waste. Many sustainable brands are shifting toward minimalist designs that use a single brand color or subtle debossing rather than full-color coverage.

This approach not only reduces ink consumption but also creates a strong, tactical, military-grade aesthetic that resonates with ammo buyers.

Eco-Friendly Finishes and Coatings

Protective coatings are often overlooked — yet they play a huge role in determining recyclability.

Hola Custom Boxes offers these sustainable finishing options:

Water-based varnish (recyclable & low-impact)

Matte uncoated finish (no plastic film)

Kraft texture lamination (earthy look, recyclable)

Natural UV coating (non-toxic, solvent-free)

All these coatings preserve your box’s print quality while keeping it fully recyclable.

How Eco-Friendly Ammo Packaging Boosts Your Brand Image

1. Positions You as a Modern, Responsible Brand

Choosing green packaging instantly differentiates you in a competitive space. Gun enthusiasts, shooting clubs, and retail buyers appreciate manufacturers that care about sustainability.

2. Enhances Brand Storytelling

Your packaging can proudly display eco-messages like “Printed with Soy-Based Ink” or “Made with Recycled Kraft Board.”

This not only educates your customers but also builds trust.

3. Expands Your Retail Opportunities

Big-box retailers and online marketplaces are adopting stricter packaging guidelines. Using recyclable, eco-certified boxes ensures smoother compliance and broader distribution potential.

Design Tips for Eco-Friendly Custom Ammo Boxes

Keep graphics minimal to reduce ink waste.

Use kraft base tones for a natural, tactical look.

Highlight caliber info clearly — sustainability shouldn’t sacrifice function.

Incorporate QR codes for digital manuals (reduces paper inserts).

Avoid metallic foils or plastic laminations when possible.

Why Choose Hola Custom Boxes for Sustainable Ammo Packaging

At Hola Custom Boxes, we combine cutting-edge design with eco-conscious production to help ammunition brands modernize their packaging responsibly.

Our Dallas-based facility offers:

Recycled kraft and FSC-certified stocks

Soy & water-based printing

Custom dielines for every caliber

Eco-friendly coatings and finishes

Fast U.S. production & delivery

We’ve helped dozens of ammo manufacturers create packaging that’s tough enough for transit yet green enough for the planet.

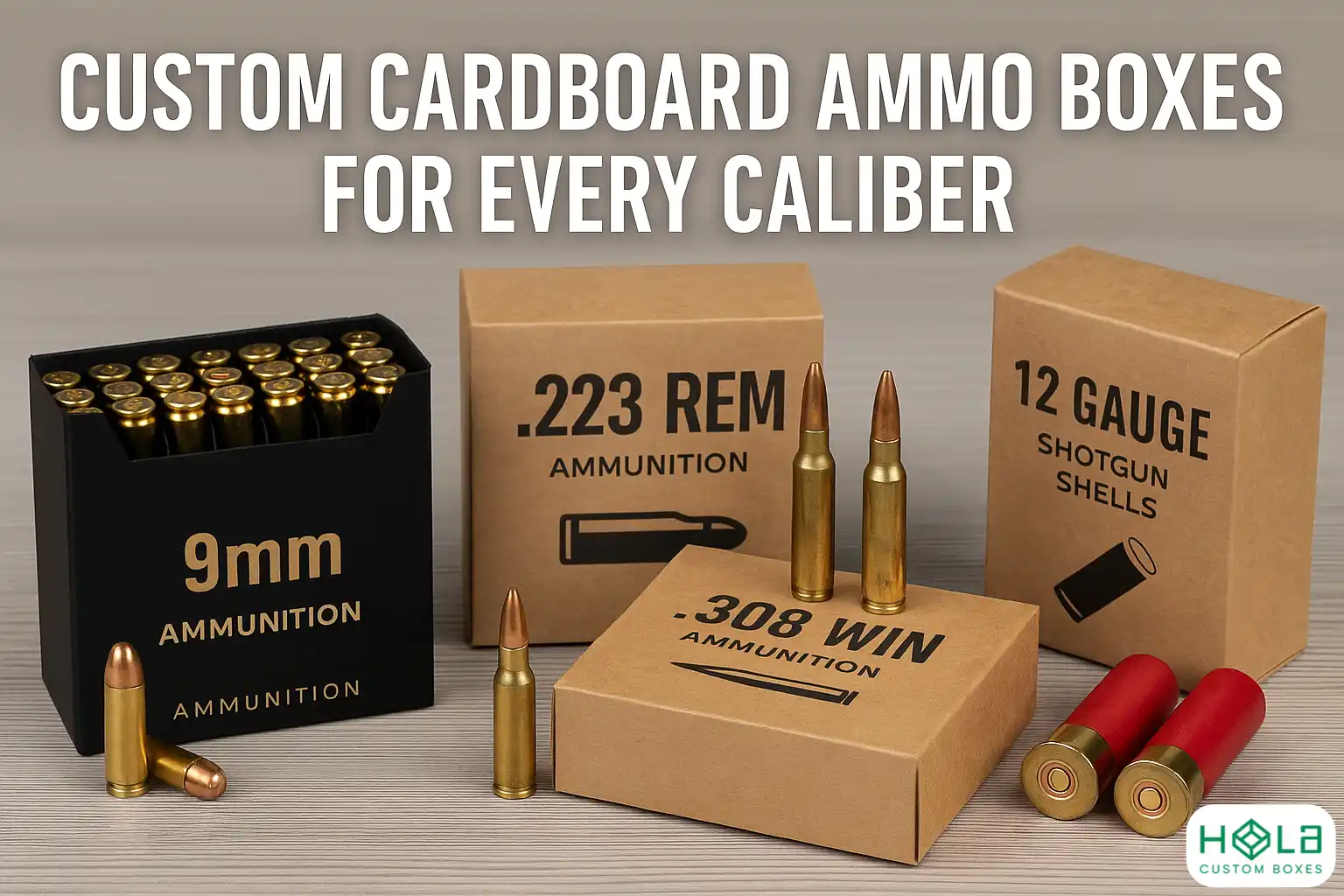

Check out our product range here → Custom Cardboard Ammo Boxes

Frequently Asked Questions (FAQs)

Q1: Are eco-friendly ammo boxes as durable as traditional ones?

Yes. With the right paperboard density and coating, eco-friendly ammo boxes provide equal protection and strength.

Q2: Can kraft packaging be printed in color?

Absolutely. Soy and UV inks produce vibrant, high-contrast prints even on brown kraft surfaces.

Q3: What’s the minimum order for eco-friendly printing?

Hola Custom Boxes supports low-MOQ runs, ideal for small or new ammo brands testing green packaging.

Q4: Are sustainable coatings water-resistant?

Yes — water-based varnishes and LED UV coatings provide moisture resistance while remaining recyclable.

Q5: Can I get mockups before production?

Yes. We offer free 3D digital proofs so you can review color and layout before printing.

Conclusion

The future of packaging — even for ammo — is sustainable. By switching to eco-friendly custom ammo box printing, you can strengthen your brand’s reputation, meet modern environmental standards, and connect with a broader audience.

Partner with Hola Custom Boxes to design packaging that’s tough, stylish, and eco-conscious — because protecting your brand shouldn’t come at the planet’s expense.

Start designing today at Hola Custom Boxes.