The Science of Paper Weight: Choosing the Right GSM for Your Custom Packaging Boxes

2025-09-29 12:15:46

The Science of Paper Weight: Choosing the Right GSM for Your Custom Packaging Boxes

When it comes to designing effective packaging, one factor often overlooked is paper weight. The thickness and strength of your packaging material directly influence durability, print quality, and overall presentation. Understanding GSM (grams per square meter) and points (pt) is critical for businesses looking to invest in custom packaging boxes that truly represent their brand.

In this guide, we’ll break down the science of paper weight, compare GSM and points, and explain how to choose the right material for your product packaging needs.

What Does GSM Mean in Packaging?

GSM (grams per square meter) measures the density of paper or cardstock. Higher GSM indicates heavier, thicker, and sturdier material. For packaging boxes:

250–300 GSM: Lightweight, suitable for inserts or sleeves.

300–400 GSM: Common for retail packaging boxes such as custom printed pillow boxes.

400–600 GSM: Used for rigid packaging, cosmetics, and luxury boxes.

Why it matters: GSM influences not only strength but also print finish, lamination quality, and customer perception of your product.

What Are Points (pt) in Paper Weight?

In North America, paper thickness is often measured in points (pt). Each point equals 0.001 inches. For example:

10 pt = 0.010 inches

16 pt = 0.016 inches

24 pt = 0.024 inches

This measurement is widely used in the packaging industry, especially for custom packaging boxes in cosmetics, pharmaceuticals, and food products.

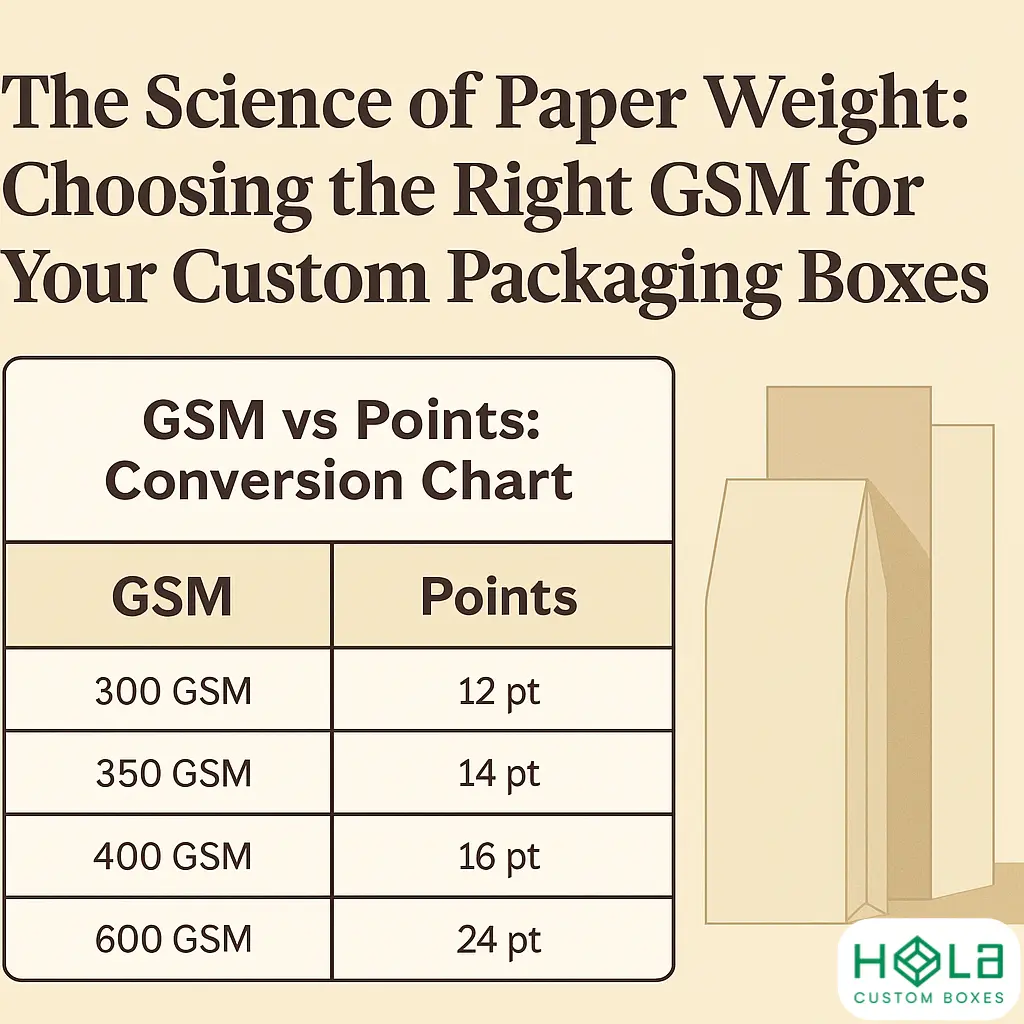

GSM vs Points: Conversion Chart

Here’s a simplified comparison chart to help you understand how GSM correlates to points:

| GSM (Grams per Square Meter) | Approximate Points (pt) | Packaging Use Case |

|---|---|---|

| 250 – 280 GSM | 10 – 12 pt | Inserts, lightweight sleeves, brochures |

| 300 – 350 GSM | 14 – 16 pt | Soap boxes, cosmetic boxes, small retail packaging |

| 400 – 450 GSM | 18 – 20 pt | Premium product boxes, rigid foldable packaging |

| 500 – 600 GSM | 22 – 24 pt | Luxury rigid boxes, perfume packaging, electronics |

| 800 – 1200 GSM | 28 – 32 pt+ | High-end rigid gift boxes, protective outer packaging |

Note: Exact conversions vary depending on material type and coating.

How Paper Weight Affects Custom Packaging Boxes

1. Durability and Protection

Heavier GSM ensures sturdier packaging, which is essential for fragile or premium products such as luxury pharma packaging.

2. Printing and Finishes

Thicker materials handle lamination, embossing, and foil stamping better, making them ideal for high-end branding.

3. Customer Perception

Lightweight boxes may feel cheap, while higher GSM communicates premium quality and trust.

4. Eco-Friendliness

Recyclable kraft boards in higher GSM support sustainable packaging goals without sacrificing strength.

Choosing the Right GSM for Your Product

Cosmetic Packaging Boxes (300–400 GSM)

Cosmetics require a balance of elegance and sturdiness. A 14 pt (300 GSM) or 16 pt (350 GSM) is ideal for serum boxes and lip balm packaging.

Food & Beverage Packaging (350–450 GSM)

Food packaging like custom noodle boxes needs grease resistance and durability. Laminated 16 pt cardstock or 400 GSM kraft board works best.

Luxury Rigid Boxes (600+ GSM)

For perfumes, jewelry, and premium electronics, rigid packaging uses 1000–1200 GSM board wrapped with printed sheets. This delivers both strength and luxury appeal.

Eco-Friendly Kraft Boxes (300–400 GSM)

For sustainable brands, kraft stock in mid-range GSM offers durability while staying recyclable.

Why GSM Matters for Branding

Your choice of paper weight directly ties into brand identity. Customers notice when packaging feels sturdy, polished, and professional. A perfume in a flimsy box reduces brand value, while one in a rigid 1200 GSM custom box enhances luxury perception.

With proper GSM selection, brands can:

Improve customer trust.

Enhance shelf presence.

Reduce returns from damaged packaging.

FAQs on GSM and Paper Weight in Packaging

Q1. What is the best GSM for cosmetic boxes?

300–350 GSM (14–16 pt) is commonly used for cosmetics like serums and lip balms.

Q2. Can I use lightweight GSM for food packaging?

Not recommended. Food packaging requires 350+ GSM for durability and hygiene.

Q3. What GSM is used for rigid boxes?

Rigid boxes often use 1000–1200 GSM board with printed wraps.

Q4. Is higher GSM always better?

Not necessarily. Lightweight boxes (250–300 GSM) are ideal for inserts and sleeves. Heavier GSM suits luxury and protective packaging.

Q5. How do GSM and points differ?

GSM measures weight per square meter, while points measure thickness in thousandths of an inch. Both help determine paper strength and usability.

Conclusion

The science of paper weight plays a vital role in the effectiveness of custom packaging boxes. By choosing the right GSM and understanding its correlation with points, brands can design packaging that ensures durability, enhances print finishes, and boosts customer trust.

At Hola Custom Boxes, we help businesses select the perfect material for their packaging needs—whether it’s lightweight kraft soap boxes, sturdy food packaging, or luxury rigid boxes.

Explore our homepage for expert solutions and browse product-specific options like luxury pharma packaging and custom noodle boxes.