Choosing the Right Material for Ammo Boxes: SBS, Kraft & Corrugated Compared

2026-02-22 13:55:45

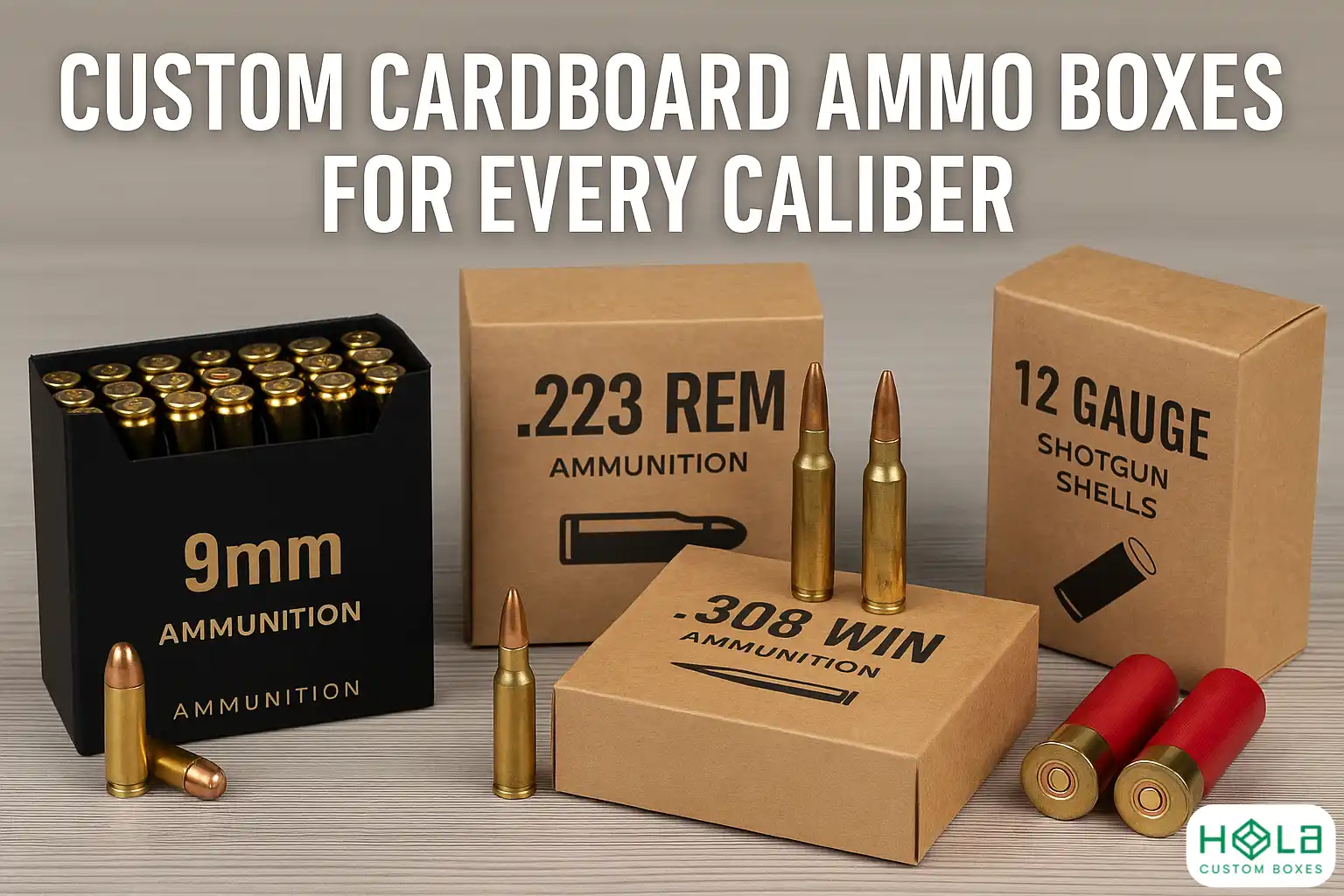

Choosing the Right Material for Ammo Boxes: SBS, Kraft & Corrugated Compared

Choosing the right ammo box board depends on print performance, structural strength, and environmental exposure verified by standard tests. At Hola Custom Boxes, substrate selection is never guesswork—it is tied to measurable compression targets, moisture thresholds, and barcode verification standards.

Whether you are developing retail cartons or ship-ready bulk packaging with a certified Cardboard Ammo Box Manufacturer, the material must align with distribution hazards, humidity exposure, and graphic requirements.

SBS (16–24 pt, C1S) delivers high-fidelity graphics, as confirmed by TAPPI brightness and rub/scuff checks, plus die-line crease trials. Unbleached kraft prioritizes tear and scuff resistance, specified by basis weight, caliper, and Cobb values, with burst/Elmendorf and glue-line peel/shear validation. Corrugated (E/B/C flutes, ECT-rated) maximizes compression, puncture, and drop absorption for shipping. The deeper comparison below clarifies stack limits, moisture targets, and print expectations.

For complete structural solutions, visit:

https://holacustomboxes.com

https://holacustomboxes.com/product/cardboard-ammo-box-manufacturer

Choose an Ammo Box Material in 60 Seconds

If a selection must be made quickly, the decision reduces to the environment and handling requirements. Steel maximizes impact resistance and long-term stacking strength. Polymer reduces weight and eliminates corrosion risk. Aluminum offers a corrosion-resistant middle ground with improved stiffness compared to polymer.

For carton-based packaging programs managed by Hola Custom Boxes, rapid validation checks may include:

Drop test from 1.2 m onto the edge and corner; the pass criteria are no lid disengagement and no latch deformation.

Compression testing to target pallet load; requires less than 5% permanent set after 24 hours.

For wet or salt exposure, confirm gasket integrity and corrosion resistance (no red rust or white oxidation after 72 hours of salt fog).

For field carry applications, measure empty mass and handle ergonomics; require a secure grip with gloves.

Validate closure cycle life (≥500 opens) and hinge play tolerance.

These performance gates ensure material decisions are validated rather than assumed.

.jpg)

SBS Ammo Boxes for Premium Retail Printing

Rapid field tests narrow the choice among steel, polymer, and aluminum for durability. However, premium retail programs often require high-fidelity shelf-facing graphics on folding cartons rather than direct printing on rigid containers.

Solid bleached sulfate (SBS) folding carton stock supports tight registration, dense ink laydown, and a consistent white point for brand color accuracy. Typical specifications range from 16–24 pt caliper with coated one-sided (C1S) surfaces optimized for offset, digital, or flexographic processes.

Verification should include TAPPI brightness/whiteness metrics, rub-and-scuff resistance testing, and adhesion testing per ASTM D3359 following varnish or aqueous coating application. Die-line trials confirm crease integrity and panel spring-back performance, while compression screening (edge crush proxy tests) verifies retail stacking performance and dimensional stability.

SBS is typically chosen when visual presentation drives shelf differentiation and when barcode clarity, brand color precision, and high-resolution imagery are primary objectives.

Kraft Ammo Boxes for Rugged Shelf Appeal

Most unbleached kraft folding cartons trade the ultra-white, high-ink-density aesthetic of SBS for a tougher, utilitarian shelf appearance and higher tolerance to abrasion.

Kraft substrates typically emphasize tear and scuff resistance, making them suitable for SKUs exposed to repeated pick-up, restocking, peg-hook display, and counter handling.

Specifications generally reference:

Basis weight

Caliper

Cobb values for moisture absorption

Burst strength

Elmendorf tear resistance

These metrics help predict edge damage at tuck flaps and corner folds. Glue-line performance is validated through peel and shear testing across temperature and humidity cycles to ensure closure integrity.

Because kraft substrates have a darker natural tone, print expectations must be managed carefully. Ink-holdout testing, dot-gain evaluation, and ANSI/ISO barcode-scan grading under intended coatings are critical. Contrast levels should be verified for warning panels and regulatory text.

Kraft is often selected when moderate cost savings and rugged shelf durability are more important than ultra-bright print reproduction.

Corrugated Ammo Boxes for Safer Shipping

While SBS and kraft folding cartons address shelf presentation and handling durability, ship-ready protection typically requires corrugated construction to manage compression, puncture, and drop risks in parcel and LTL distribution networks.

Corrugated ammo boxes are specified by:

Flute profile (E, B, or C)

Combined board strength

Edge Crush Test (ECT) rating

E-flute supports compact retail cartons with improved rigidity and print surface quality. B-flute increases stacking strength. C-flute enhances cushioning performance.

Ship-ready sets often incorporate partitions, pads, or trays to immobilize cartridges and prevent primer-to-primer contact. Moisture management is controlled through liner selection, sizing treatments, and tape specification validated under conditioning cycles.

| Parameter | Typical Spec | Verification |

|---|---|---|

| Board grade | 32–44 ECT | COA, incoming audit |

| Flute choice | E for compact, B for rigidity | Pack trial |

| Closure | 48–72 mm tape, H-tap | Process check |

Corrugated is generally the preferred substrate for bulk distribution, e-commerce channels, and ammunition case packs.

Ammo Box Durability Compared: Crush, Puncture & Drop

In parcel and LTL networks, three failure modes typically determine survival: compression under stack load, puncture from concentrated impacts, and drop shock at edges and corners.

Compression testing (ASTM D642) typically shows single-wall corrugated delivering the highest top-to-bottom strength at practical calipers, with ECT/BCT targets defined by gross weight and pallet pattern. Kraft paperboard follows, while SBS exhibits lower column stability unless upsized.

Puncture testing (ASTM D781 or ISO 3036) demonstrates corrugated’s liner-and-medium structure resisting point loads more effectively than solid paperboard of similar basis weight.

Drop testing (ASTM D5276) reveals that corrugated flutes absorb energy, whereas solid boards transmit greater shock, increasing corner-crushing risk.

These performance comparisons guide substrate selection based on actual distribution hazards.

Moisture & Storage Performance by Material

Mechanical performance alone does not define packaging durability. Moisture uptake and storage conditions frequently determine whether an ammo box maintains stiffness, closure retention, and print legibility.

SBS typically exhibits higher Cobb60 absorption than unbleached kraft. Without moisture barriers, SBS softens more rapidly at relative humidity levels of 80–90%.

Kraft demonstrates improved wet strength and lower edge wicking, retaining fold memory more effectively under humidity cycling (e.g., 24 hours at 90% RH followed by 24 hours at 50% RH).

Corrugated provides cushioning but is highly sensitive to liner and medium moisture content. ECT ratings and flute stability decline significantly after conditioning at 23°C/85 % RH.

Storage recommendations typically include:

23°C / 50% RH control

Desiccant use for extended storage

Defined water-vapor transmission targets for coatings

These controls ensure dimensional stability and barcode reliability over time.

Printing, Labeling & Barcode Performance

Traceability depends on durable identifiers. Print and labeling systems must be specified for substrate compatibility and validated after conditioning and handling.

SBS supports higher line-screen offset printing and tight dot gain control. Ink rub resistance should be tested per ASTM D5264, including post-pack scuff testing.

Uncoated kraft requires higher ink laydown; minimum optical density must be defined, and feathering and mottle evaluated.

Corrugated liners may require preprint processes or high-build flexography. Registration accuracy and edge crush effects on barcode zones must be verified.

Pressure-sensitive labels should be qualified for:

Fiber tear

Cold adhesion

Humidity cycling

Barcodes should specify symbology, X-dimension, quiet zones, and ISO/IEC 15416 scan grades of C or higher after drop and abrasion testing.

Best Ammo Box Material by Use Case & Budget

Substrate selection should align with validated performance targets rather than aesthetics alone.

For retail cartons emphasizing premium graphics and controlled shelf handling, SBS is often preferred. Caliper, stiffness, and coating specifications should be verified against rub-resistance and barcode-grade standards.

For cost-sensitive SKUs with moderate scuff exposure, unbleached kraft offers durability at a lower material cost. Tear strength, abrasion resistance, and Cobb moisture limits should be defined.

For e-commerce distribution, bulk packs, and case shipments, corrugated provides superior stacking and drop protection. Flute profile and ECT ratings should be validated against ISTA drop and vibration protocols, with label adhesion confirmed after temperature cycling.

At Hola Custom Boxes, substrate decisions are driven by measurable performance metrics and total landed cost analysis rather than assumptions.

Final Thoughts

Material selection should always be validated against performance requirements. SBS is preferred when high-resolution CMYK graphics, tight die-cut tolerances, and retail presentation are primary objectives. Kraft offers higher perceived toughness and improved scuff resistance at moderate cost with acceptable print outcomes. Corrugated provides superior edge-crush strength and cushioning for parcel networks, reducing drop-and-puncture failures.

The final choice should be based on defined ECT/BCT targets, humidity exposure conditions, barcode grade requirements, and total landed cost.

For engineered substrate solutions from a proven Cardboard Ammo Box Manufacturer, explore:

https://holacustomboxes.com

https://holacustomboxes.com/product/cardboard-ammo-box-manufacturer

Performance should be specified.

Verification should be documented.

And the material should match the mission.