Choosing the Right Material for Ammo Boxes: SBS, Kraft & Corrugated Compared

2026-01-17 12:50:49

Choosing the Right Material for Ammo Boxes: SBS, Kraft & Corrugated Compared

At Hola Custom Boxes, we work with ammunition brands, distributors, and retailers who face the same decision every day: which ammo box material actually fits the job?

SBS, kraft, and corrugated each solve a different problem. SBS delivers a clean, premium retail look with sharp printing, but it’s less forgiving under rough handling. Kraft offers a tougher, more practical appearance that hides wear and performs well in daily use. Corrugated is the safest option for shipping and long-term storage, though it adds bulk.

The right choice depends on where your ammo boxes will be used, how they’re handled, and what conditions they’ll face next.

Main Points

SBS works best for premium retail packaging where shelf appearance and print clarity matter most.

Kraft balances durability and cost, making it ideal for everyday counter sales and range use.

Corrugated provides the highest crush and puncture resistance for shipping and storage.

Moisture exposure, climate swings, and handling conditions should guide board grade and coatings.

Total cost should include board weight, inserts, closures, finishes, and reject rates—not just raw stock.

Ammo Box Material Checklist: Strength, Moisture, Print, Cost

A smart ammo box material decision starts with four fundamentals: strength, moisture resistance, print performance, and total system cost.

Start by estimating your load. Loose rounds, tray-packed ammo, or mixed calibers all require different edge crush and puncture resistance. Heavier loads demand stronger board grades.

Next, map the storage and handling environment. Ammo stored in humid basements, vehicle trunks, or field conditions may need coatings, poly liners, or space for desiccants to prevent rust and board swelling.

Printing is non-negotiable. The surface must support barcodes, lot numbers, safety markings, and compliance text without smearing or scan failures. Not all boards accept inks and finishes equally.

Finally, calculate the full system cost—board grade, die-cutting, inserts, closures, coatings, and expected reject rate. At Hola Custom Boxes, we always optimize for reliability first, because packaging failures cost more than material upgrades.

SBS Ammo Boxes: Premium Retail, Sharp Printing

When shelf presence matters, SBS (solid bleached sulfate) is the premium choice. Its bright white surface delivers exceptional color accuracy, tight registration, and fine detail—ideal for caliber callouts, safety icons, and branding.

SBS die-cuts cleanly, allowing precise tuck ends, windows, hanger tabs, and tamper features without fiber tearing. Creases stay sharp, corners stay square, and boxes look consistent across production runs.

For high-touch retail environments, SBS also accepts coatings and laminations evenly, improving scuff resistance and fingerprint control. If your ammo packaging needs to communicate quality at first glance, SBS performs exceptionally well.

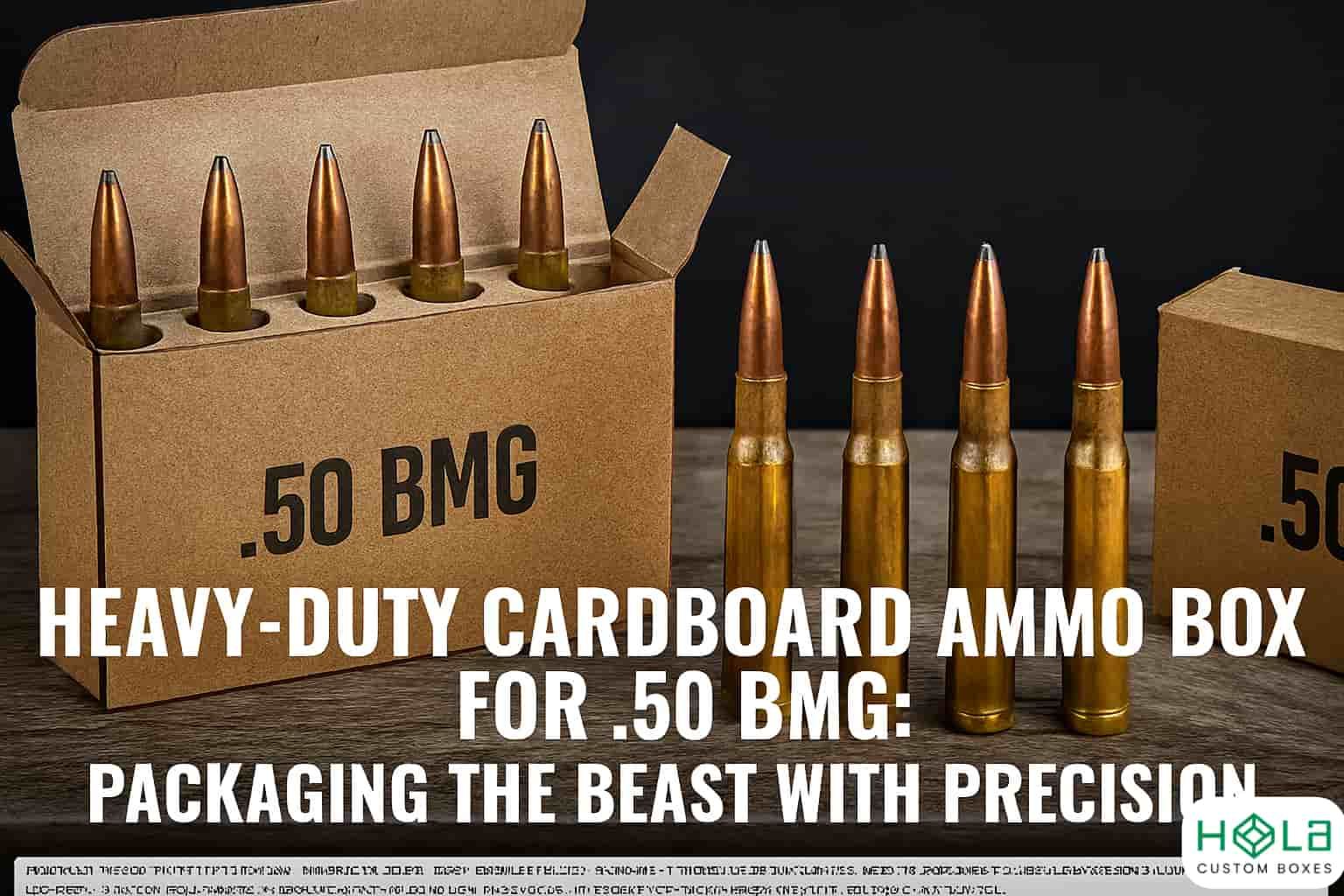

Kraft Ammo Boxes: Tough Look, Solid Value

Kraft ammo boxes offer a rugged, workmanlike appearance that fits the category and keeps costs under control. The natural brown surface hides scuffs, fingerprints, and light abrasion better than bright white paperboard.

Kraft supports bold one- or two-color printing that feels authentic and purposeful. It stacks well, handles repeated handling, and stays presentable in retail, lockers, or range bags.

For brands balancing presentation and durability, kraft is often the smartest middle ground—stronger and more forgiving than SBS, without the added cost of premium whiteness. Matte or aqueous coatings can further improve rub resistance when needed.

Corrugated Ammo Boxes: Safest Choice for Shipping

.jpg)

If your ammo packaging must withstand parcel carriers, pallets, and long-distance transit, corrugated board offers the highest level of protection.

The fluted structure absorbs shock, resists crushing, and protects corners during stacking and conveyor handling. Corrugated provides superior puncture resistance when cartons rub against straps, pallets, or rough surfaces.

It also performs better under varying climates, helping boxes stay square and labels remain readable. You can specify single-wall or double-wall construction, adjust caliper, and add inserts or dividers to prevent rattling and primer impact.

While not designed for high-gloss retail display, corrugated prints cleanly for logistics, compliance panels, and branding—and coatings can improve moisture and scuff resistance.

Choosing an Ammo Box Material by Use Case (Quick Guide)

Every ammo box lives a different life. Some sit under bright retail lights, others ride in range bags, and many travel thousands of miles through shipping networks.

For premium retail presentation, SBS delivers the cleanest print and sharpest structure—but needs controlled handling.

For everyday carry and counter sales, kraft hides wear, handles light moisture better than SBS, and keeps costs reasonable.

For shipping and long-term storage, corrugated provides unmatched crush strength and cushioning, especially for heavier calibers.

In wet or high-humidity environments, coatings or liners should always be considered regardless of material.

Frequently Asked Questions

Are SBS, Kraft, and Corrugated Ammo Boxes Legally Compliant for Retail Sales?

Yes. All can be compliant if federal, state, and carrier regulations are met. Packaging must follow DOT, UN, and retailer-specific labeling and quantity requirements.

Which Material Best Reduces Rattling During Transport?

Corrugated performs best due to its cushioning flutes, especially when combined with inserts or dividers. Paperboard options tend to transmit more noise.

Do These Materials Affect Barcode Scanning or Label Adhesion?

Yes. SBS offers the best scan accuracy. Kraft requires stronger adhesives. Corrugated often benefits from liner labels or flat panels.

Can Ammo Boxes Be Reused Safely?

Yes, with inspection. Most boxes last 3–10 cycles depending on load, moisture exposure, and handling.

What Temperature Ranges Do These Materials Handle?

SBS: ~0–120°F

Kraft: ~-10–140°F

Corrugated: ~-20–150°F

Dry storage is critical for all materials.

Final Thoughts

At Hola Custom Boxes, we help ammo brands choose materials based on real-world use—not guesswork.

If shelf appeal and clean graphics matter, SBS delivers a premium retail finish.

If you want durability, authenticity, and cost control, kraft is a reliable everyday option.

If shipping strength and long-term protection are critical, corrugated is the safest choice.

Always factor in handling, climate, and load conditions. The right material isn’t the cheapest—it’s the one that prevents failures, protects your product, and keeps your brand compliant and credible.

If you need help selecting the right ammo box material, Hola Custom Boxes provides expert guidance, custom dielines, and production-ready solutions built for real conditions.