Assessing the Endurance of Paper-Based Ammunition Storage

2026-01-19 07:07:28.jpg)

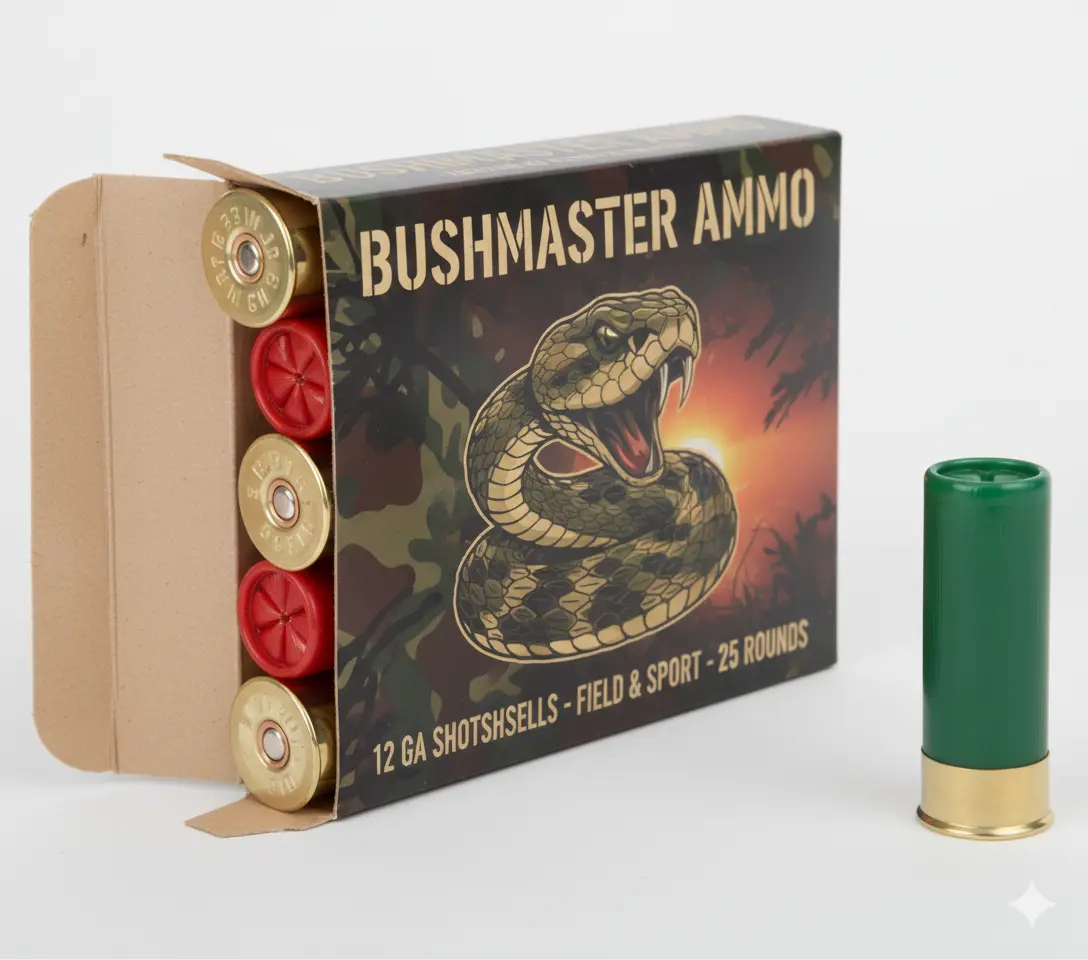

Historical Usage of Cardboard Ammo Boxes

In the world of ammunition storage, the adage “a house is only as strong as its foundation” rings especially true. Paper-based storage solutions, particularly cardboard ammo boxes, have played a significant role in ammunition logistics for decades.

Historically, cardboard ammo boxes were widely used for both military and commercial storage and transport of ammunition. Early designs relied on basic folding techniques, but over time, these boxes evolved to include reinforced corners, improved fluting, and sturdier closures to handle heavier loads. Manufacturers also introduced internal dividers and tray systems to stabilize cartridges and reduce movement during transport.

To extend service life, preservation techniques advanced alongside box design. Waterproof coatings, wax treatments, and improved adhesives helped protect cardboard ammo boxes from moisture intrusion. These innovations enabled cardboard packaging to remain a practical, lightweight, and cost-effective solution for ammunition storage, particularly for bulk transport and short- to mid-term storage.

At Hola Custom Boxes, modern cardboard ammo packaging continues to build on these proven foundations by combining engineered board grades with precision die-cutting and structural reinforcements.

Factors Affecting Cardboard Box Durability

.jpg)

The durability of cardboard ammo boxes depends heavily on both material quality and environmental exposure. The manufacturing process itself plays a decisive role. Board grade, flute structure, wall thickness, and adhesive strength all contribute to load-bearing capacity and resistance to deformation.

External conditions further influence performance. Prolonged exposure to temperature fluctuations, high humidity, or direct moisture can weaken fiber bonds, reduce compression strength, and compromise seams. Handling stress during stacking or transport also affects long-term durability.

For ammunition packaging, these factors must be carefully balanced. At Hola Custom Boxes, cardboard ammo boxes are engineered with specific edge crush ratings, moisture-resistant coatings, and optional inner liners to mitigate these risks and improve structural consistency.

Impact of Environmental Conditions on Cardboard Boxes

Environmental exposure is one of the most critical variables in cardboard endurance. Extreme heat can dry out fibers, making them brittle, while excessive cold can reduce flexibility and increase the likelihood of cracking under load.

Humidity poses an even greater threat. Moisture absorption can soften cardboard, reduce its compression strength, and cause warping. Over time, this can compromise not only the box itself but also the ammunition inside.

Insect activity is another concern in uncontrolled storage environments. Pests such as termites or beetles can damage cardboard walls, creating entry points that expose ammunition to contaminants.

For this reason, cardboard ammo boxes should always be stored in controlled environments with stable temperature and humidity levels. When properly stored, well-manufactured cardboard boxes can perform reliably for extended periods.

Testing Methods for Assessing Cardboard Box Endurance

To accurately evaluate the performance of cardboard ammo boxes, standardized testing methods are essential. Compression testing measures a box’s ability to withstand vertical load without collapsing, a critical factor for stacked ammunition storage.

Moisture resistance testing assesses how well the box maintains integrity when exposed to elevated humidity or incidental moisture. This includes evaluating coatings, liners, and adhesive performance under stress.

At Hola Custom Boxes, these tests help ensure that cardboard ammo packaging meets the mechanical demands of real-world storage and transport while maintaining consistency across production runs.

Recommendations for Long-Term Storage With Cardboard Boxes

For long-term ammunition storage using cardboard boxes, specific best practices should be followed to minimize degradation and risk:

Cardboard boxes should be stored in dry, well-ventilated spaces away from direct ground contact. Using shelving or pallets helps prevent moisture transfer and pest exposure.

Proper labeling and organization are essential. Clearly marked calibers, quantities, and dates improve inventory control and reduce unnecessary handling that can weaken packaging over time.

For extended storage or harsh environments, additional protective measures, such as inner poly liners, desiccants, or secondary outer cartons, may be advisable.

While plastic or metal containers may offer superior protection in extreme conditions, properly engineered cardboard ammo boxes—when used within their design limits—remain a dependable and efficient solution.

Final Thoughts

Cardboard ammo boxes have a proven history rooted in practicality, efficiency, and adaptability. Their durability depends not only on material quality but also on environmental conditions, testing standards, and proper use.

When designed with purpose and manufactured to specification, cardboard ammunition packaging can deliver reliable performance without unnecessary bulk or cost. At Hola Custom Boxes, these principles guide the development of custom cardboard ammo boxes built to balance strength, protection, and real-world usability.