Punch Partition

Recyclable punch partitions (interlocking dividers) engineered to fit your products and box—strong, space-saving cell grids for glass, jars, candles, and kits. Low MOQ (100+)

Punch Partition

Custom Punch Partitions – Impact-Ready, Cost-Efficient & Exact-Fit Protection

Keep products separated, centered, and safe. Hola Custom Boxes engineers die-cut punch partitions (cross partitions) that interlock into strong cell grids—perfect for bottles, jars, candles, glassware, cosmetics, and multi-SKU kits. They ship flat, set up fast, and are fully curbside-recyclable. Low MOQ from 100 units with free proofs and fast U.S. shipping.

Why Choose Hola Punch Partitions

-

Low MOQ from 100 — ideal for launches, seasonal sets, and test shipments.

-

Exact-fit cells — we size cell width/height to your product diameters, shoulders, and caps.

-

Strong yet light — kraft chipboard or corrugated (E/B/C/BC flute) tuned to weight and drop risk.

-

Fast assembly — interlocking slits, clear notch IDs, ships flat to save space.

-

Stacking support — options for layer pads, top caps, and neck-lock collars for bottles.

-

Brand/lot marks — simple one-color orientation codes or part IDs if needed.

-

Plastic-free & recyclable — paper-based protection that meets eco goals.

-

Quick turn — typically 8–12 business days after proof approval.

Best-Fit Use Cases

-

Bottles & Jars — sauces, beverages, skincare, perfumes

-

Candles & Home Fragrance — jar security without foam →

-

Beauty & Wellness Kits — serums, droppers, lotions, minis →

-

E-commerce & Subscriptions — inner grid + branded outer →

-

Retail/Wholesale Shippers — pair with sturdy outers →

Partition Styles & Options

-

Interlocking Cross Partitions — classic grid (2×2, 3×3, 4×3… any matrix).

-

Bottle Neck-Lock — die-cut rings to stabilize necks and prevent clink.

-

U-Channel & Edge Guards — add perimeter protection inside the shipper.

-

Layer Pads & Cap Sheets — separate vertical tiers; improve top load.

-

Combo Trays — mix partitions with insert trays for accessories

-

Quick-ID Notches — etched letters/numbers on tabs for fast assembly.

Materials & Specs

-

Chipboard / Paperboard (18–28 pt) — compact packs, light/medium loads.

-

Corrugated

-

E-flute: sleek print, lighter items.

-

B-flute / C-flute: stronger cells for glass/ceramic.

-

BC double-wall: heavy bottles, industrial parts.

-

-

Finishes: usually uncoated kraft for friction and eco; optional white or clay-coated.

-

Printing: orientation marks, QC codes, or simple branding upon request.

(We’ll recommend cell clearance and board caliper based on your product size/weight and ship test goals.)

Design Tips That Survive Shipping

-

Target snug but not tight cells; allow modest clearance for labels and taper.

-

For tall bottles, add neck rings or shoulder collars to stop rocking.

-

Use layer pads between tiers; cap with a sheet for top-load strength.

-

Share ship method (parcel/LTL) and drop specs; we’ll spec flute and slot geometry accordingly.

What to Send for Quoting

-

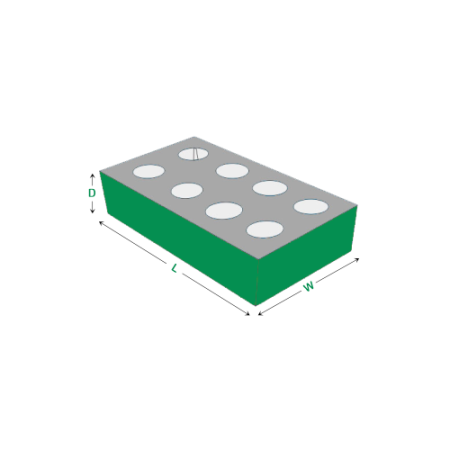

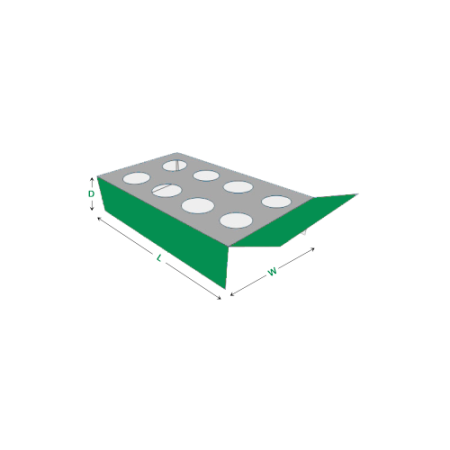

Outer box internal size (L × W × H) or link to your box.

-

Product dimensions & weight (diameter/width, height, shoulder/neck if any).

-

Count & arrangement (e.g., 3×4 grid; single or stacked tiers).

-

Channel (e-commerce, wholesale, retail shipper) and any compliance needs.

Related Solutions

-

Display Packaging (PDQs for inner packs)

How to Order Punch Partitions

-

Request a Free Quote — cell matrix, product sizes, material, quantity → https://holacustomboxes.com/request-a-quote/

-

Approve Free Proofs — dieline + 2D/3D mockups; cell clearance, slots, and tiering confirmed.

-

Production & QC — crush tests, clean die-cuts, tab accuracy.

-

Delivery — free USA shipping; international options available.

FAQs – Punch Partitions

Q: What’s the minimum order quantity?

A: 100 units per partition size/configuration.

Q: Will these fit my existing mailer or shipper?

A: Yes—share internal box dimensions; we’ll design to fit and can adjust the box if needed (see Corrugated link).

Q: Which material should I choose for heavy glass?

A: B/C flute or BC double-wall with layer pads and neck-locks for stability.

Q: Can I stack two tiers in one box?

A: Absolutely—use partitions + layer pads; we’ll model top load and clearance.

Q: Are they reusable?

A: Many clients reuse kraft/corrugated partitions for in-house moves and returns; durability depends on load and handling.

Q: Can you brand or color-code the parts?

A: Yes—simple one-color IDs, arrows, or brand marks help assembly and QC.

Q: Typical turnaround time?

A: Usually 8–12 business days after proof approval.

Protect every unit. Pack faster. Ship with confidence.

Request your free quote

| 1 |

Available in all custom sizes |

|---|---|

| 2 |

CMYK, PMS, Foiling, Spot UV, Embossing, Plastic Window. |

| 3 |

10pt to 28pt (60lb to 400lb) Kraft, Eco Friendly, E-flute. |

| 4 |

Starts from 100 boxes. |

| 5 |

Gloss/Matte/Uncoated. |

| 6 |

Die cutting, pasting, perforation. |

| 7 |

Digital Proof With 2D & 3D view. |

| 8 |

Fastest Turnaround time. |