Master The Art Of Box Measurement: Boost Packaging Success

2026-01-03 13:05:20

Accurate box measurements are critical to the success of custom packaging. In fact, a study conducted by packaging experts at PakFactory revealed that 85% of businesses experienced a significant reduction in material usage and production costs by ensuring precise box dimensions.

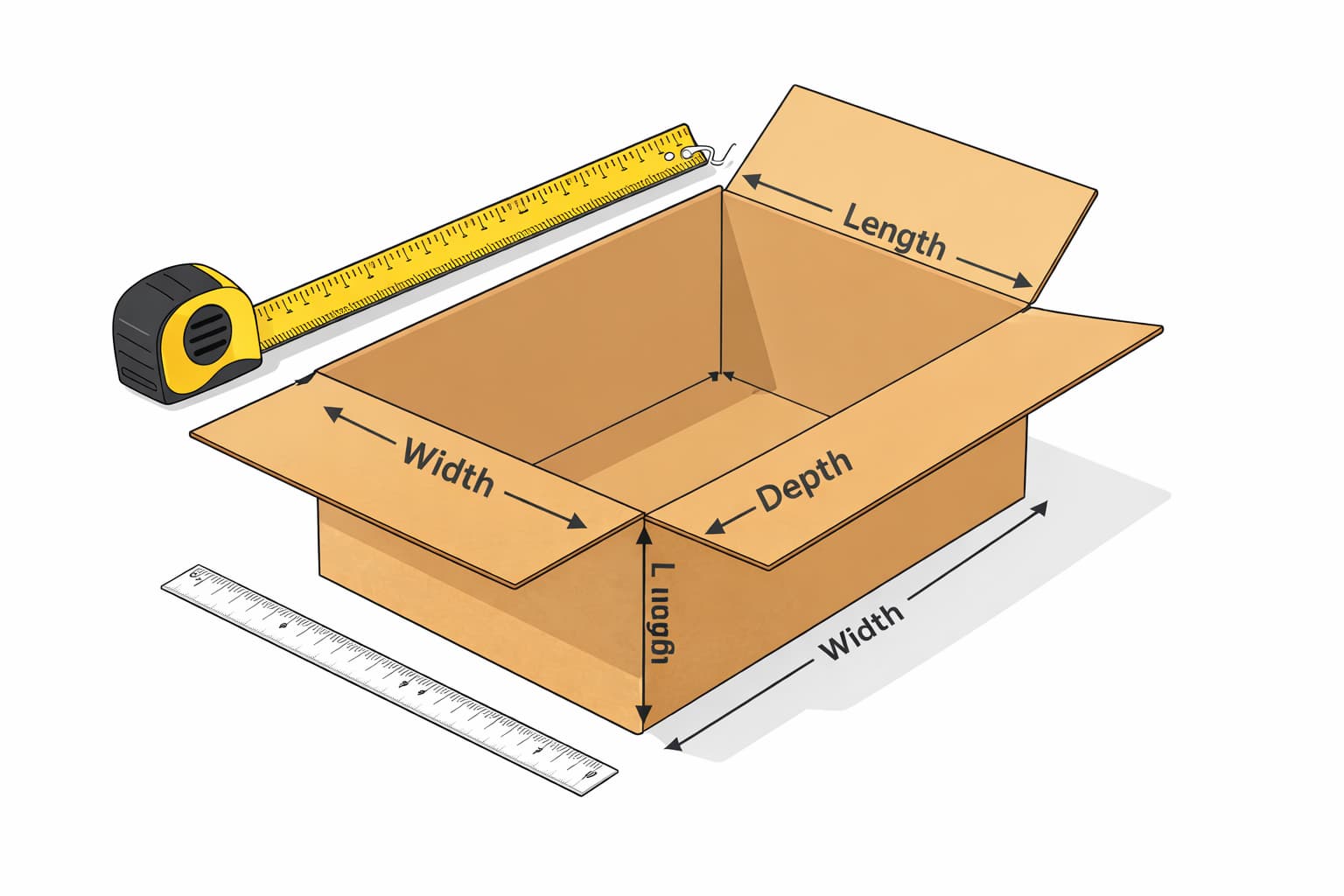

The length, width, and depth of a box influence not only the product's fit but also its shipping and warehousing requirements. Understanding the distinction between depth and height, and measuring the internal dimensions, is crucial for minimizing product movement and creating a tailored packaging solution.

External dimensions alone may lead to ill-fitting packaging, as they do not account for box thickness, particularly in corrugated boxes commonly used in packaging.

By mastering the art of box measurement, businesses can ensure a proper fit, optimize their packaging process, and establish a consistent brand identity that enhances their product marketing.

Key Takeaways

- Accurate box measurements are crucial for custom packaging and can impact materials, production costs, and shipping.

- Measuring the internal dimensions of a box is essential for accurate packaging that fits the product and ensures product security.

- External dimensions may not account for box thickness, leading to ill-fitting packaging.

- Calculating box volume by multiplying length, width, and depth can help determine product fit, shipping, and warehousing needs.

Why Box Dimensions Matter

Box dimensions play a crucial role in custom packaging as they directly impact materials, production costs, and shipping, making it imperative to accurately measure the length, width, and depth/height of a box. Accurate measurements minimize damage and reduce overall costs.

Calculating the volume of a box, which is determined by multiplying the length, width, and depth, helps determine the product fit, shipping needs, and warehousing requirements. Additionally, box dimensions significantly impact shipping costs. By having precise measurements, companies can ensure that the packaging fits the product properly, reducing the risk of damage during transportation.

Moreover, knowing the dimensions of a box is vital for estimating packaging materials and production expenses. Therefore, mastering the art of box measurement is essential to boosting packaging success and optimizing logistics.

The Power of Packaging Design

Once you’ve built a loyal customer base and established repeat sales, the next step is ensuring your bath bomb brand captures attention in retail spaces. Packaging plays a vital role here—it should not only reflect your brand identity but also stand out on crowded shelves. Using bold colors, creative graphics, and distinctive shapes can immediately grab attention, while clear labeling of scents, ingredients, and unique product features helps shoppers make quick and confident decisions.

Turning Packaging into a Marketing Tool

Beyond aesthetics, packaging can also serve as a marketing tool to boost credibility and trust. Highlighting customer testimonials, reviews, or brand values directly on the packaging can influence buying decisions and strengthen retailer confidence in stocking your products. By blending eye-catching design with informative and trust-building elements, your packaging becomes more than just a container—it becomes a powerful tool to maximize shelf appeal and spark retailer interest.

Understanding Length, Width, and Depth

Understanding the dimensions of a container, specifically length, width, and depth, is essential for ensuring precise measurements in packaging. Accurate measurements are crucial for calculating box volume, which helps determine product fit, shipping, and warehousing needs.

To achieve accurate measurements, keep a few tips in mind. First, it is essential to measure the internal dimensions of the box rather than relying solely on the external dimensions. This ensures product security and minimizes movement within the packaging.

Additionally, it is recommended to use the standard order of LxWxD or LxWxH for the dimensions. Finally, it is essential to consider the thickness of corrugated boxes, as this can affect the overall measurements.

By following these tips, packaging professionals can achieve precise measurements and boost their packaging success.

Importance of Internal Dimensions

Precise measurements of internal dimensions are essential for ensuring product security and minimizing movement within the packaging, thereby improving packaging performance. According to a study conducted by packaging experts, companies that prioritize accurate internal measurements experience a significant reduction in product damage during shipping, resulting in a 20% decrease in overall costs.

Accurate measurements offer several advantages, including the ability to create packaging that fits the product perfectly, thereby reducing the risk of damage from movement during transit. Incorrect measurements, on the other hand, can lead to ill-fitting packaging, resulting in product damage and increased costs.

Additionally, inaccurate measurements can lead to inefficient use of warehouse space and increased shipping expenses. Therefore, companies must invest in precise measurement techniques to optimize packaging success and minimize costs.

Expert Guidance and Resources

Expert guidance and resources are crucial for optimizing packaging strategies and minimizing costs in the packaging industry. Staying up to date with packaging industry trends is essential to ensure packaging remains practical and relevant.

Professional packaging assistance offers a multitude of benefits, including expertise in accurately measuring box dimensions. By relying on packaging experts, businesses can avoid costly mistakes and ensure that their products are packaged securely and efficiently. These professionals have in-depth knowledge of various packaging materials, structures, and printing techniques, enabling them to provide valuable advice and recommendations.

Additionally, they can help create a consistent brand identity through packaging and innovative design elements. Utilizing expert guidance and resources is a wise investment for businesses looking to boost their packaging success and stay ahead of industry trends.

Frequently Asked Questions

Can I use external dimensions to determine a product's fit in a box?

External dimensions alone cannot accurately determine a product's fit in a box. Fitting accuracy requires measuring internal dimensions, accounting for box thickness, and considering the product's shape and fragility.

How does the fluted texture of corrugated boxes affect the measurements?

The fluted texture of corrugated boxes can affect measurement accuracy. The flutes add thickness to the box, altering the internal dimensions and potentially leading to ill-fitting packaging. Measuring fluted boxes accurately is essential for packaging success.

Why is it important to measure the internal dimensions of a box?

Measuring the internal dimensions of a box is essential for ensuring product security and minimizing movement. Accurate box measurements ensure proper packaging that fits the product and reduces the risk of damage during shipping.

What are some potential issues that can arise from using the wrong measurement for length, width, or depth?

Using the wrong measurements for length, width, or depth of a box can lead to potential issues such as ill-fitting packaging, damage to the product, increased production costs, and inefficient use of warehouse space. Accurate box measurements are crucial for successful packaging.

How can packaging experts from PakFactory help ensure accurate box measurements and successful packaging?

PakFactory's packaging experts can ensure accurate box measurements and packaging success by leveraging their expertise in box measurement. Accurate measurements are crucial for packaging success as they minimize damage, reduce costs, and ensure proper product fit.