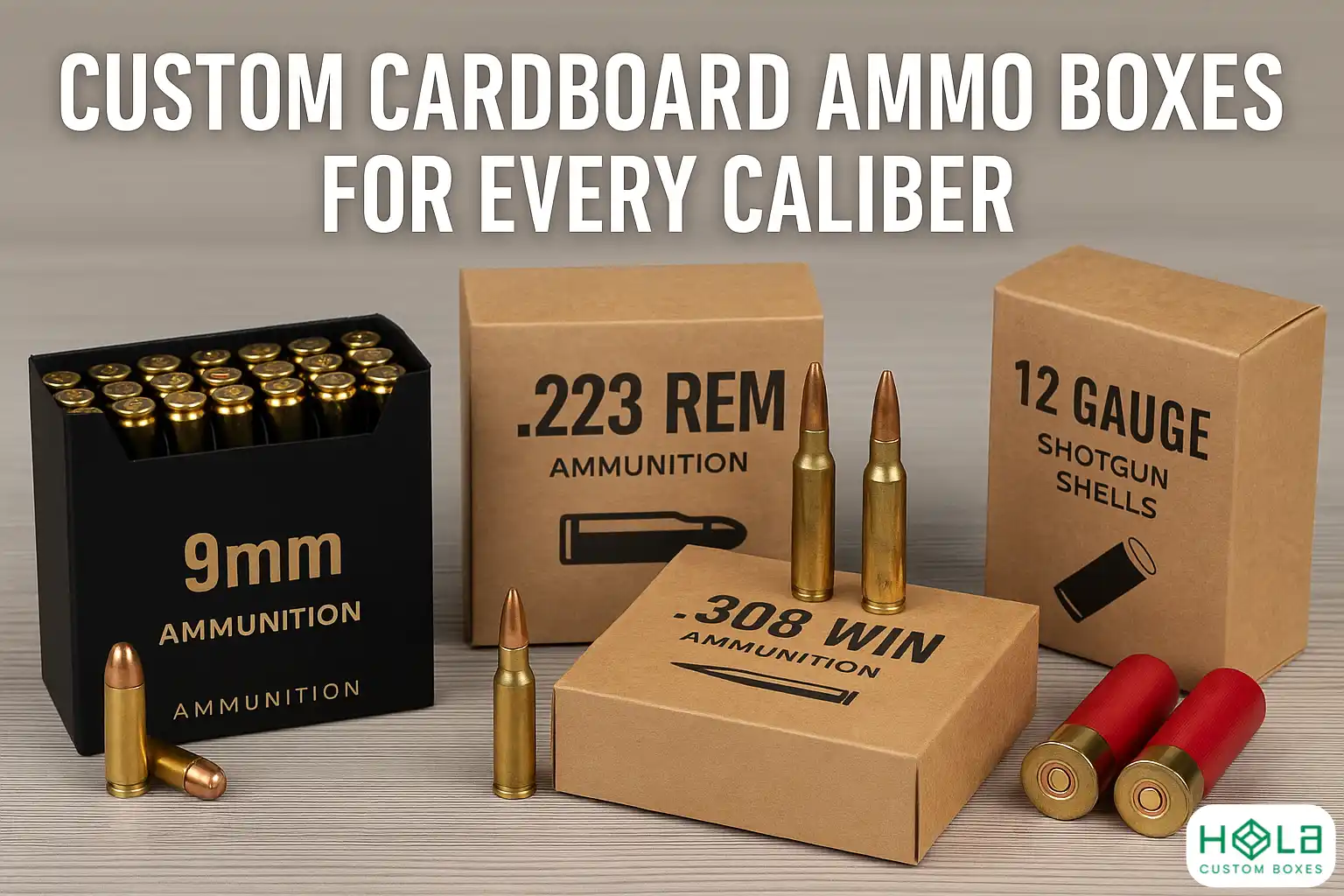

From 9mm to .50 Cal: A Manufacturer's Guide to Wholesale Custom Cardboard Ammo Boxes

2025-09-28 10:11:43

From 9mm to .50 Cal: A Manufacturer's Guide to Wholesale Custom Cardboard Ammo Boxes

For ammunition manufacturers and wholesale distributors, packaging is the critical bridge between production and safety compliance. It’s not just about containing rounds; it’s about providing crush resistance, protecting against moisture, maintaining compliance with hazardous materials regulations, and serving as a vital branding tool. Generic containers simply don't suffice when dealing with the diverse and precise world of calibers, from the high-volume 9mm cardboard ammo boxes to the heavy-duty demands of .50 Cal ammunition packaging. This guide provides a comprehensive overview for manufacturers navigating the custom cardboard packaging landscape, focusing on safety, structural integrity, and logistical efficiency in wholesale custom cardboard ammo boxes.

Engineering Strength: Choosing Material for Heavy-Duty Ammunition Packaging

The structural integrity of the box is the first line of defense for both the product and the handlers. Unlike common consumer goods, ammunition requires packaging built for weight, density, and potential stacking stress.

Selecting the Right Board Grade and Strength

For the manufacturer's ammunition packaging, the material choice is usually a high-grade corrugated cardboard or durable paperboard. The crucial metrics here are:

Edge Crush Test (ECT): This measures the cardboard’s ability to withstand stacking pressure. For dense, heavy rounds like .45 ACP ammo boxes, a high ECT rating (e.g., 32 ECT or higher) is essential to prevent crushing during palletization.

Bursting Strength (Mullen Test): This measures the force required to rupture the board, important for containing the weight and preventing blowouts.

Choosing the correct board thickness and flute size (e.g., E-flute for smaller boxes like .223 cardboard ammo boxes, or C/B-flute for larger, bulk containers) ensures optimal protection without unnecessary bulk. Working with a dedicated cardboard ammo box manufacturer ensures these precise engineering requirements are met for every caliber you produce.

Caliber-Specific Design and Internal Structuring

One size does not fit all in the world of ballistics. Effective packaging must be customized to the exact dimensions and weight distribution of the rounds it holds, from pistol ammunition to rifle rounds.

Precision Inserts for Optimal Caliber Fit

A loose box can allow rounds to shift, leading to damage or inaccurate round counts. Custom sized cardboard ammo boxes require precision internal components:

Die-Cut Trays/Inserts: These are custom-molded or die-cut cardboard trays designed to hold a specific number of rounds (e.g., 50 rounds for 9mm) in individual slots. This not only protects the brass casings from rubbing but also facilitates quick counting and handling.

Dividers and Partitions: For bulk cartons of loose rounds, reinforced partitions prevent the concentration of weight in one area, distributing the load evenly and maximizing the box's stacking capacity.

Water-Resistant Coatings: Ammunition must be kept dry. Investing in cardboard with moisture-resistant finishes or coatings is vital for preserving primer integrity and preventing corrosion during long-term storage or shipment.

Whether you need packaging for compact .40 S&W rounds or large hunting cartridges, the internal structuring must guarantee stability and protection.

Navigating Compliance: Hazardous Materials and Caliber Labeling

Ammunition is regulated as a hazardous material (Hazmat, Class 1.4S), making packaging compliance non-negotiable. Manufacturers must ensure their wholesale ammunition packaging meets strict Department of Transportation (DOT) and United Nations (UN) standards.

Mandatory Markings and Color Coding

The box must clearly, legibly, and permanently display all required markings:

UN Specification Markings: Certification that the packaging has passed performance tests.

Proper Shipping Name: E.g., "Cartridges for weapons, inert projectile."

Hazard Division: Typically 1.4S for small arms ammunition.

Manufacturer/Distributor Name: For traceability.

Beyond regulatory mandates, high-visibility, accurate caliber labeling on cardboard boxes is essential for user safety and inventory management. Many manufacturers use a distinct color-coding system (e.g., red for 9mm, blue for .223) to quickly identify the caliber, preventing misfires or logistical errors in a high-speed warehouse environment.

Logistics and Operational Efficiency in Ammo Distribution

For wholesale custom cardboard ammo boxes, efficiency means optimizing for machine packing, pallet stacking, and warehouse storage. Poorly designed boxes lead to slow production lines and wasted space.

Standardization for Automation

Custom sizing should be designed around your specific loading equipment. Boxes must be uniform and easily foldable for automated erection and filling processes. Furthermore, the final exterior carton size should be optimized for standard pallet dimensions, maximizing the number of rounds that can be shipped on a single pallet, thereby reducing freight costs in ammunition distribution.

Branding and Retail Presence

While safety is primary, the box remains a critical sales asset. Custom printed ammunition boxes showcase your brand’s logo, unique selling propositions (like powder type or bullet composition), and commitment to quality. A professionally branded box, whether featuring vibrant digital printing or simple, clear flexography, elevates your presence in the firearms and sporting goods market. Start designing your compliant and efficient packaging solution by visiting our homepage.

Conclusion: Custom Boxes as the Foundation of Your Ammo Business

From the smallest 9mm round to the largest .50 Cal cartridge, the choice of packaging is fundamental to the safety, compliance, and profitability of your ammunition business. By choosing wholesale custom cardboard ammo boxes that are engineered for high-density weight, designed with caliber-specific internal structures, and marked clearly for regulatory compliance, manufacturers ensure a smooth flow from the assembly line to the customer. Custom packaging is more than just a container; it is a seal of quality and commitment, safeguarding your product and strengthening your brand authority in a demanding industry.